Soichiro Honda Founded His Company In The Ashes Of Postwar Japan

Behind every great car company is an ingenious founder. Henry Ford overcame repeated failure to start Ford Motor Company and change the way we build automobiles. William C. Durant displayed considerable business intuition when he consolidated the most popular automakers of the early 1900s and established General Motors. And Ferruccio Lamborghini started his company simply because he thought he could build a better car than Enzo Ferrari. Perhaps the person that best exemplifies the qualities of a founder is Soichiro Honda.

Like Ford, he bounced back from countless missteps and grew wiser because of them. He predicted industry trends and bent the market to his will, much in the same way Durant did in the emerging automotive scene. And time and time again, he set new, higher standards for others to follow. His company was founded in the ashes of postwar Japan and grew to become the planet's largest producer of motorcycles. They also became champions on the racetrack on both two and four wheels. And he oversaw an unlikely entrance into the world of cars and laid the groundwork down for one of the most dominant automakers in the world. This is the story of Soichiro Honda: King of the Motorcycles.

A LIFELONG DREAMER

November 17, 1906. In Komyo Village, on the outskirts of the coastal town of Hamamatsu, Gihei and Saki Honda bore their first son, Soichiro. Although he’d come to be one of 9 children, only four of them would reach maturity. Half of his siblings were affected by the lack of adequate medical care in rural Japan and succumbed to childhood disease.

Soichiro had been surrounded by machines pretty much since birth. As a youth, his grandfather would carry him on his back and take him to the local rice polishing mill. Mills in these days were usually powered by steam. This one utilized a gasoline engine. a bit strange under normal circumstances, and very unusual in these parts. Watching the motor go to work, with blue smoke and the smell of petrol in the air, became one of his favorite pastimes. No doubt the biggest influence on him during his formative years was his parents.

His mother was a master weaver and there was rarely a loom issue that she couldn’t fix. Gihei should’ve been another in a generations-long line of farmers. Instead, he broke away from tradition and became a blacksmith by trade. He repaired a variety of items, but he found stable work in bicycle restoration. The elder Honda often made the 150-mile trip north to Tokyo to purchase broken-down bikes, fix them up, and sell them for a meager profit. The family endured grinding poverty, but this side job helped them carve out a living. Soichiro was involved with the forge as well, though his early dealings didn’t make much of an impact. In between the small jobs that were assigned to him, his father kept him busy by having him form shapes from the malleable shapes that came from the furnace.

When he was 8, he heard there would be a plane stopping by the imperial army regiment in Hamamatsu. He was anxious to have his first look at an airplane, but there was just one problem. The regiment was about 20 kilometers away from his village. There was no way his parents would let him go that far a distance unsupervised. So he devised a foolproof plan. He swiped 2 Sen, stole his father's bicycle, and made the trek anyway. He was a child trying to ride a bike made for an adult. He had to put one leg through the crossbar and ride it askew because he wasn't tall enough to sit on the seat. Riding in that compromised position must've been quite a challenge, but he did manage his way over.

One obstacle gave way to another, though, as found that the entrance fee was actually 10 Sen. As he was turned away from the front, he eyed a towering pine tree nearby. He climbed it, and from a high branch, he had a clear view of the action. Still fearing he’d get caught, he broke off a few nearby branches and made a makeshift shelter that hid him from view. His father was waiting for him when he came back home later that night. He was missing cash, his bike, and most importantly, his son. Gihei grilled him and demanded to know where he’d gotten off to. Soichiro came clean. Instead of completely losing his cool, his father’s demeanor changed completely. He’d never seen an airplane up close before, so for the rest of the evening, they discussed what the experience was like.

And he’d never forgotten the first time he saw an automobile. He eyed a sedan maneuvering through his village’s narrow streets and immediately gave chase. Either the car was pretty slow or the young Soichiro channeled his inner Olympic sprinter because he actually managed to grab onto its rear bumper for a moment. It came to a stop and a stream of oil came from its undercarriage. It took off, but his attention was now turned toward the puddle. He got on all fours and took deep breaths of it. He was hooked. He scooped it up and rubbed it all over his hands, arms, and face.

With his mind focused purely on machines, his grades in elementary school were, predictably, terrible. Soichiro didn’t like reading or writing, hated calligraphy, and was hopeless during his examinations. That is when he actually bothered to show up at all. He’d frequently skip class, often going to a hill behind the school to stare up at the clouds. He did begin to warm up to schooling when science and engineering became more integrated into his curriculum, but higher education wouldn’t be in the cards. After 8 years of schooling, he took an alternate path into the auto industry.

While leafing through an issue of a trade magazine his father received in the mail, Soichiro happened upon a help wanted ad. It was from Art Shokai, an auto service station in Tokyo. He applied without hesitation and, shortly after, was told to come to Tokyo at once to start working. Soichiro was elated, but his father was weary of sending his 15-year-old son to the nation’s capital. He did finally relent, thanks partly to Soichiro’s persistence, and allowed him to take up the job offer. He packed together his few belongings and set off for the big city.

Soichiro was hardly prepared for what Tokyo had in store for him. The first thing he took note of upon his arrival was the prevalence of the automobile. He saw one car in his village a month if he was lucky. In Tokyo, he could see ten of them at the same time. With all of the vehicles roaming around, there wouldn’t be any shortage of work at Art Shokai. The higher-ups wouldn’t have any choice but to immediately put him in the shop, he thought. He walked in and met with the owner. It turns out, he already had a task in mind that was suited for Soichiro’s natural mechanical inclination: babysitting. He left behind everything he knew to have the owner’s child strapped to his back for hours at a time. The hours gave way to days, which turned into weeks, which faded into months.

Neither the low pay nor the snide comments from the technicians bothered him very much. What killed him was the fact that what he felt was his life’s purpose was within grasp, yet he was making no progress toward achieving his goal. Doubt crept into his mind. Perhaps he was destined to be a sitter for the rest of his life. The one thing that kept him from packing up and heading back home was the shame of facing his parents. So he stuck it out, as he thought anything would be preferable to that.

Art Shokai was one of the few auto shops in Tokyo at the time. Business took off as the city’s infrastructure became better equipped to accommodate them. Things got so busy that the owner pulled Honda from his babysitting duties and told him to help out. The jobs given to him for the next year and a half were nearly as menial as his tasks at his father’s forge, but finally moving into shop work represented the fulfillment of a months-long goal. Another opportunity for him to advance in the company would turn up, though under tragic circumstances.

The Great Kanto Earthquake of 1923 completely leveled Art Shokai. Nearly every employee left the shop to look after their loved ones. The only two that remained were the senior apprentice and Honda. The two of them got things up and running again by fixing up vehicles that were destroyed at a nearby assembly plant. A shortage of materials and Honda’s own lack of shop experience meant the repairs weren’t of the best quality. The most excruciating part of the process was fabricating replacement wheels. The spokes were made of wood in these days. Many of them were damaged or destroyed in the firestorms that littered the country’s midlands following the quake. They were able to improvise new ones with what they had, but that was the most dreaded part of any repair.

At the suggestion of the owner, Honda used his spare time after hours to work on a racing car. He labored on it from 8 PM to midnight every night for months. He frankensteined together parts from various cars to make two machines. Powering them were modified 8L Curtiss-Wright aircraft engines he got as surplus at an airbase near Chiba.

In 1928, the owner of Art Shokai wanted to expand and thought Soichiro was the perfect person to represent the brand elsewhere. Over the past six years, he felt he’d acquired the skills necessary to run a shop of his own. He opened his own branch in 1928 in Hamamatsu, an arms throw away from his hometown. His father showed his appreciation by building him a small house and giving him a bag of rice “so he wouldn’t starve.” He probably meant this figuratively, but that was a real possibility in the early goings of the shop.

Although Honda proved himself as an exceptional mechanic at Art Shokai, potential customers were wary of handing their cars off to someone so young. They preferred to get repairs at a number of other shops in the area, ones that were run by more “experienced” technicians. Honda’s shop would have to live off of the scraps these other places cast aside. He gained a reputation for taking on jobs others put off as lost causes. At the end of the year, they were in the black. The shop made a profit of 80 Sen or about 2 cents. It didn’t matter how far in the black he was. He was just thrilled to have managed a successful business. If things went well going forward, he figured he could save a nest egg of 1000 yen before retirement.

The shop may have been his primary focus, but that wasn't the only thing he was working on. In 1931, he invented a wheel with cast iron spokes. They were more durable than the wooden ones from his Art Shokai days. They caused a stir at a National industrial exhibition and Honda began receiving licensing offers from abroad. In a few months’ time, he was getting checks for 1000 Yen every month.

Soichiro became a living legend in Hamamatsu. Stories spread around town that detailed his eccentric style, ones you may have even heard. On one occasion he was driving a car that was packed full of geisha. He was so intoxicated from the festivities earlier in the day that he drove straight off of a bridge and into a river. Luckily, it wasn’t a very far trip down and a pool of mud softened the impact. Another time, he got into a heated argument with a tax official. He was set on having the final say in the matter, so he hooked up a fire hose and waited for the person to leave. The instant he saw them, Soichiro doused them in water.

At a local festival, he and a friend were taking in the events at a club. The details became more sparsely recalled as he downed more drinks, but he remembers being told something he didn’t like by a geisha. The comments sent him into a blind fury. He picked her up and tossed her out of a nearby window. He sobered up real quick when sparks flew up into view. Expecting the worst, he looked down and saw her alive and well, but suspended in a mess of power lines. When they cut her down, the electricity went out all over the city. These exploits earned him a column in the paper: “The Arto Shokai on the Rampage.” It expressed frustration “that a man of 25 could afford such sprees which even men of 40 and 50 could not afford.”

He also poured every spare moment he had into his racing endeavors. His new car was powered by a supercharged Ford engine that was tilted a bit to the left. Races in Japan were run counter-clockwise, so the layout helped him cut into left-hand corners with a bit more precision.It was tested at the All Japan Speed Rally at Tama River on the outskirts of Tokyo. Soichiro was out in front and barrelling toward the finish line at 75 miles per hour, but disaster struck when a car that was in the pits cut in front of him. They collided. Honda was ejected from his seat as the car flipped over 3 times.

He regained consciousness in a hospital sometime later a bit worse for wear. The entire left side of his face was broken and he suffered a dislocated shoulder. His brother Benjiro was in the car and was seriously injured as well. This spelled the end for Soichiro’s racing career. During the 18 months he spent recovering, he pondered the other ways he might get involved in the automotive industry.

TRIAL AND ERROR

Getting into the production of piston rings seemed like the obvious choice. In the late 30s, a piston ring was worth more than solid silver of the same weight. He established the Art Piston Ring Research Institute in 1936, hiring 50 workers and purchasing very expensive tools to make it happen. Friends and family expressed their concerns about his new business. He was making an extreme financial commitment to produce something that he had little experience with. His response to them was “I can build anything if I see it just once.”

He poured molten metal into a dye, forming a cast-iron lump of metal that closely resembled a piston ring. Don’t let the appearance fool you. His creation had no elasticity and therefore couldn’t handle the stress of being in an engine. They made more effective paperweights than anything. Honda, probably realizing he was a bit hasty with this whole thing, sought the advice of local foundries. These establishments wouldn’t simply part with their secrets. They outright demanded that he take on an apprenticeship with them. Soichiro figured his days of learning behind someone else were behind him.

He turned down their propositions and set about picking up on everything on his own. He and another associate locked themselves inside of their factory at all hours of the day. They’d stay up until 2 in the morning studying casting, then spend the rest of their waking hours trying to apply what they learned. He stopped at nothing to decipher the formula at the cost of his own well-being. He neglected himself so much that his wife had to come to the factory to cut his overgrown hair. Throughout all of this misery, he was no closer to producing a quality piston ring. The situation became desperate. The company was hemorrhaging cash and his wife was forced to sell off her own jewelry to keep the lights on. If he didn’t figure out something soon, the more than 4 dozen workers that he brought on would be put out on the streets.

To say that Soichiro Honda looked down on formal education would be an understatement. He came to own his own repair shop and patented one of the more significant developments in early automotive history without it. He was at his wit's end and needed to put this behind him if he wanted to save his company from the brink. He asked Takashi Tashiro, an instructor at Hamamatsu High School, for advice. Tashiro had a quick look at one of his piston rings and determined that it didn’t have enough silicone.

This blew Soichiro’s mind. He didn’t even realize silicone played that much of a factor in piston ring construction. If he learned this much from the first few minutes of their meeting, then what other techniques could he gather from a full course in metallurgy? He enrolled in the school on a part-time basis, applying what he learned in class to his business. His progress increased significantly, and on November 20th, 1937, he produced piston rings that were, in his words “more or less acceptable.”

He religiously attended lectures, but his elementary school habits would crop up soon enough. One day, the principal called Soichiro into his office and told him that he wouldn't be earning his degree. Throughout the course of his attendance, he never bothered to take a single exam. Honda retorted, saying the degree would be worth less than a movie ticket. “At least with the latter you're guaranteed entrance into the theater. The diploma doesn't guarantee that you'll make a living.” He was expelled but continued to attend lectures for another year as an unregistered student.

In 1939, he stepped down as president of Art Piston and brought his expertise to Tokai Seiki Heavy Industries as director. Their client list grew as the quality of their products improved, and the most important among them was Toyota. They eventually purchased a 40 percent stake in the company. TSHI even expanded outside of their niche when they designed machine tools for creating aircraft propellers. Before this invention, the construction of the wooden propellers could take upwards of a week. This new machine could grind down the surfaces of two at the same time. The entire job could be finished in as little as 30 minutes.

The good times wouldn’t last for very long. The factory was damaged when American planes bombed the nearby Hamamatsu Air Base. An earthquake not long after completely destroyed it. Toyota wanted him to supply them with other components after the war, though he didn’t take them up on it. He wanted to take a few months off and see where the country stood then. Piston rings had been their golden goose for years, but with strict manufacturing restrictions on the horizon following the war, it was impossible to gauge what their demand would be in the near future.

He sold them all of his company stock for 450,000 yen and took what he referred to as a "human holiday." It was a year-long layoff that he used to do nothing in particular. He purchased a barrel of medical alcohol, brought it home, and, from it, engineered his own synthetic sake which he shared with all of his friends. He picked up the shakuhachi, a traditional Japanese flute. He even spent time as a science and technology instructor for the Iwata Police Department. The human holiday ended as he thought he found an opening in the fabric industry.

Hamamatsu was the center of japan's textile scene, and this only rang truer after the Gachaman boom following the war. Soichiro wanted to capitalize on this by creating a rotary loom. The machines at the time only moved horizontally, but he envisioned a machine that would also move vertically. Ultimately, this project was abandoned after he realized how much it would cost to make it a reality. It was chalked up as a failure, but he wouldn’t have to wait on his next opportunity for long.

FROM ASHES

Japan's transportation infrastructure was in shambles after the war. Automakers were banned from creating passenger cars, the roadways were decimated, and their railway lines lay in twisted heaps of scrap metal. It was in this devastation that Soichiro seized upon his next business venture. It was painfully obvious that reliable transportation was in great demand in these years. With cars being well out of reach for much of the population, many people preferred to get around via bicycle.

They were cheap, nimble, had virtually no running costs, and could be loaded down with plenty of supplies. Soichiro wanted to take them a step further by motorizing them. For as effective as they were, bikes could only go as far as their owners were physically able to take them. Motorized vehicles would broaden their infrastructural borders and, hopefully, help the country get back on its feet. This wasn’t a new idea by any means. The practice of clipping a motor onto a bike was commonplace in Europe. A few of these machines even made their way to Japan. These were niche products before. With the current conditions, He was certain the potential market for them would be significantly widened.

In September of 1946, he established Honda Gijutsu Kenkyujo or Honda Technical Research Institute. Its base of operations was a small warehouse that was built where the Tokai Seiki factory stood. There were about a dozen machine tools outside and a single belt-driven lathe inside.

He focused his attention on the engines that powered the radio sets that the Japanese army used during the war. These had since been decommissioned and he was able to purchase them as surplus. Each one was taken apart and their inner mechanisms modified to suit their new lease on life. In a pinch, he saw a hot water bottle in his home and thought it would make the perfect fuel tank. Speaking of which…

Gasoline restrictions threw Soichiro for a loop. Each person had a finite supply, and most would rather not use their share to fill up their gas tank. He found a way around this by making use of an alternative fuel. The tail end of the war effort saw the government scramble to find substitutes for common materials. They were running critically low on plane fuel, so one of their many ideas involved swapping it out for turpentine oil.

A large-scale effort was made to gather as many pine tree roots as possible, but this plan never fully materialized. Honda would use this experiment as his own jumping-off point. He purchased an entire forest and undertook all aspects of turpentine production himself. Instead of digging them out like before, he planned on speeding up the process by setting off dynamite at the base of the trees. Explosives and foliage don’t mix. They actually started a fire that burned down most of the pineland that he just bought. The fire department quelled the flames before the entire plot was taken, so it wasn’t a total loss.

The improvised fuel mix was unrefined, inefficient, and didn’t burn very well. Owners had to wait upwards of half an hour before the engine would kick on. Despite this drawback, the motorbike became quite popular. After building 500 or so bikes, their steady supply of surplus engines had run dry. Rather than close up shop and move on to something else, Soichiro and his team developed one of their own.

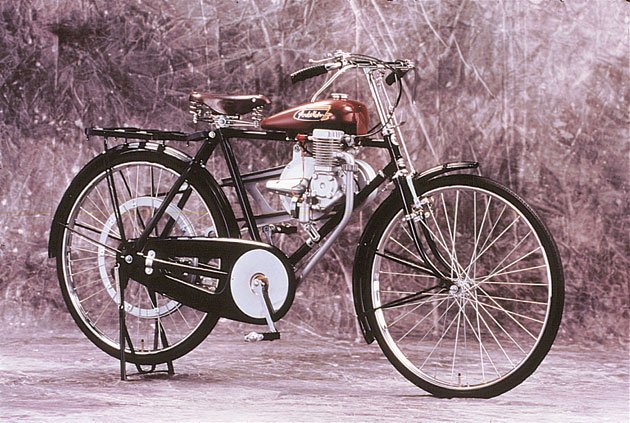

Their first creation had a strange outwardly-protruding cylinder head. It made riding ergonomics a bit awkward, but it ran even better than their previous effort. The company built upon this with the introduction of the A-Type engine in November of 1947. Its components were made with die-casting, which yielded better results than sand-casting. They also had to shoulder the immense cost of creating the metal dies. Using this method at their production rate made it nearly impossible to turn a profit. Soichiro had his eye on the long game. By sacrificing short-term gains for higher quality products, they would be able to win the goodwill of the public and pry customers away from the competition. Customers colloquially referred to the A-type as the “bata bata,” a play on the distinctive sound it made while running.

Honda A Type

It was their biggest success yet. Their own factories were constantly out of stock because engines were called for as soon as they came off the assembly line. The customer base could often be placed in one of two camps. The first comprised bicycle shop owners that simply affixed them to their own bicycles. The second group consisted of dealers on the black market. They slapped them on whatever frame they could find, threw on a set of wheels lifted from a trailer cart, and unloaded them onto unsuspecting people.

As successful as this venture was, Soichiro wanted to get into producing full-on motorcycles. He sensed that people would soon move onto sturdier, more efficient machines. He wanted to produce motorcycles completely on his own. This was an ambitious goal. No one, not even the most prominent players in the motorcycle world made both frames and engines in-house. He also wanted to move operations out of Hamamatsu and set up shop in Tokyo. People became weary of his flamboyant mannerisms; his extravagant parties, the loud motorcycles, even his penchant for red shirts wore them thin. It wasn’t a great fit.

Tokyo, on the other hand, was where much of Japan’s postwar recovery was happening. He’d be able to play a part in this as well as collaborate with like-minded people. All of this would require a significant amount of capital. He hadn’t saved up nearly enough on his own to start the new company. He wasn't having any luck finding a business partner in Hamamatsu, either. There were people willing to work with him, but Soichiro felt they were more concerned with getting a short-term return on their investment than anything else.

Colleague Hiroshi Takashima caught wind of Honda’s plight and paid him a visit. Takeshima, then an official at the Ministry of Commerce and Industry, got to know Soichiro while working at the Nakajima Aircraft Company. This wasn’t so much of a business meeting as it was a way for Takeshima to feel out the situation. Honda made it clear what he was looking for in his ideal associate, saying

“I’m great at building things, but what I need is money. I’ve had a few offers from the Gachaman crowd in Hamamatsu, but these people invariably want a say in the business. I wonder if there’s anyone in Tokyo who might be willing to put up the money.”

The meeting ended without anything of note being hammered out and the two went their separate ways. They ran into each other two years later in Tokyo’s Shinbashi district, and the conversation they’d had so long ago sprung up from the back of Takeshima’s mind.