The Rotary Engine was Mazda’s Greatest Achievement

Genuine breakthroughs in today’s industry are rare. The massive leaps that were common in the early days have given way to gradual, incremental improvements. In this unforgiving landscape, they’ll take whatever advantage they can get. So just imagine if manufacturers had the chance to make their cars lighter, quieter, more agile, and simpler.

Such an opportunity presented itself in the early 1960s, with the advent of rotary engine technology. It had the potential to give automakers an edge over their rivals. That is, if they could overcome the technical hurdles. Many companies tried to make it a viable alternative to the piston engine. Industry titans spent untold sums trying to bring them to market. Just a handful of makes managed to build rotary-engined cars in some capacity. Most of them either cut their losses early or went bankrupt trying to see them through. Only one automaker successfully produced them at scale: Mazda.

THE FOUNDING OF MAZDA

For centuries, fishing has been a pillar of Hiroshima’s culture. Jujiro Matsuda, born on August 6, 1875, seemed poised to join the industry. He was the 12th son of a fisherman, and at least a few of his siblings were in the family business. Jujiro’s father passed away when he was three, and he soon found himself on the fishing boat with his brothers. He appeared destined to carry on his legacy. Alas, Jujiro’s destiny lay elsewhere. At 13 years of age, he left for Osaka and took on a job in a blacksmith’s shop.

He outgrew his assistant role and established his own business at 19. At its peak, the firm employed 50 people. Unfortunately, a recession forced the firm to close its doors after just a year of operation. Jujiro left Osaka and found work elsewhere, but returned at the age of 31 to start another business. Matsuda Seisakusho operated out of a 33-square-meter converted cowshed. Although it was a more successful venture than his previous effort, Jujiro’s time at the helm would be fleeting. He was forced out of the company in a takeover bid.

Jujiro, determined to find success in business, reorganized the company with a loan from four friends. His previous failures prepared him well for this endeavor. It landed a lucrative contract with the government for 4 million pieces of artillery fuses. In light of its renewed focus, it changed its name to the Japan Armament Manufacturing Company.

The enterprise employed 4,000 people. Business was booming, but Jujiro wanted to relocate the company to Hiroshima. The other directors were against the move, so he went ahead and started a new company in his hometown. Later, the Nihon Steel Manufacturing Company absorbed this firm. This would have been a fitting end to his story: A fisherman’s son who left his hometown, became a self-made businessman, and returned to where it all started. Little did he know, this was merely the start of a new chapter in his life.

TOYO CORK COMPANY

The onset of World War I had far-reaching global ramifications, including the disruption of European cork production. Japan relied heavily on these exports. Luckily, an adequate substitute could be made from the bark of the Abemaki tree. Toyo Cork Kogyo, founded in 1920, filled this newfound demand.

Once the hostilities ended and European cork returned to the market, the firm hit a rough patch. A group of Hiroshima investors purchased and restructured the company. Now, it was known as Toyo Cork Kogyo Company Limited. This investment group included Jujiro, who became one of the company’s directors after the acquisition. When the firm’s president fell ill and resigned, Jujiro stepped in to fill the post.

He tried to widen its scope by offering a range of cork products, but it became apparent that the material could only take the company so far. It needed to expand into a different, more stable niche. A devastating 1925 fire only emboldened Jujiro to make a pivot. The blaze killed several employees and left the company in considerable debt. Contracts from the Imperial Japanese helped pull Toyo Kogyo out of its troubles, though military work wouldn’t be in its long-term plans, either.

Its future fortunes would lie in the transportation industry. What inspired this change in direction? The Great Kanto Earthquake of 1923. The 7.9 magnitude earthquake ravaged Tokyo and Yokohama. Over 110,000 people lost their lives in the carnage. Damages were in excess of 6.5 billion JPY, an amount that historian Charles Schencking says was about 4 times larger than Japan’s national budget for 1922. Foreign utility vehicles aided recovery efforts. From that moment, Jujiro had been taken with automobiles. Now, with the company at a crossroads, he saw an opening.

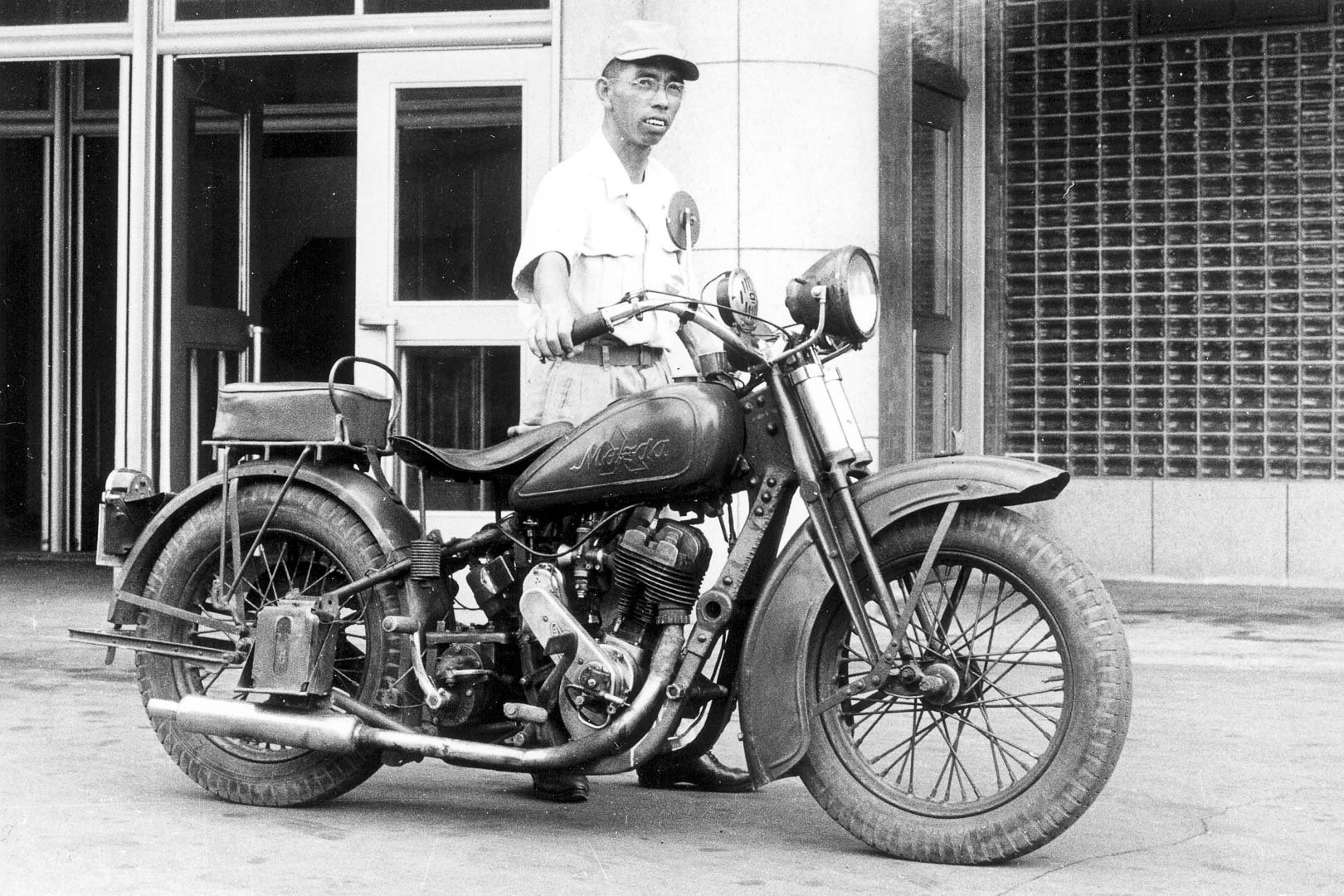

The burgeoning manufacturer, now known as Toyo Kogyo Kaisha Limited, built a batch of 250cc motorcycles in 1930. It saw early success in competition. In one race, its machine bested a British-made Ariel. Toyo Kogyo proved that it could build stout, reliable motorcycles. Prospects in this business seemed promising, though the company only made 30 of them before shifting its focus once again.

Toyo Kogyo introduced the Mazda GO-DA in 1930. The three-wheeled truck featured a motorcycle front end and a large cargo bed at the rear. According to the automaker’s website, Mazda came from Jujiro’s family name. It was also associated with Ahura Mazda, the god of light in Zoroastrianism. A familiar diamond logo was placed on the fuel tank. This is because Mitsubishi sold the vehicles through its distribution network until 1936. Toyo Kogyo’s humble pickup was significant because many other Japanese manufacturers either based their cars on foreign designs or licensed them outright. Toyo Kogyo produced models of its own design.

In 1940, the company produced a 4-wheeled passenger car dubbed the PKW. The start of World War II dashed any production aspirations. Toyo Kogyo spent the next half-decade in wartime production.

WORLD WAR II

Jujiro always treated himself to a haircut for his birthday. He did just this when he turned 70. The shop opened at 7:30 AM, and Jujiro wanted to get his haircut out of the way early so that he could return to his duties at the office. Another patron had the same idea. Jujiro, not wanting to be second in line, picked up his pace and just beat the other person inside.

He walked out of the shop thirty minutes later with a sharp new cut. By 8:15, the boss was on his way back to company grounds. Suddenly, a shockwave rippled through the area, wresting control of the car from his driver. It careened off the road and ejected both occupants from their seats. They suffered minor injuries but were able to walk away from the crash. What could that have possibly been?

That day was August 6, 1945. The United States just dropped the Little Boy atomic bomb on Hiroshima. It killed an estimated 140,000 people, or about 30 percent of the city’s population. Hundreds of thousands more were injured. Jujiro lost his youngest son. A Japanese Nostalgic Car piece quotes an Autonews article, which states that the bomb detonated a mere 50 yards from the barber shop. If he had been second in line, then he would have been killed as well. Toyo Kogyo’s headquarters was in ruins. Its factory, located in the nearby suburb of Mukainada, was intact save for some shattered windows.

Toyo Kogyo did its part to help Hiroshima recover. Its factory served as a hospital, city hall, police station, courthouse, and newspaper office. Production of three-wheeled vehicles resumed four months after the bombing. The scars of that tragic event will never truly heal, but Hiroshima showcased immense resilience in the face of unimaginable hardship. In a way, Toyo Kogyo would embody this strength to take on the challenges ahead.

THREAT OF CONSOLIDATION

Jujiro stepped down in 1951, allowing his son Tsuneji to assume the presidency. The company expanded its operations after the war. By 1954, commercial vehicle production was a tick above 32,000. With the release of the R360 kei car in 1960, Mazda began building models for the general public. Toyo Kogyo didn’t officially change its name to Mazda until 1984, but I will be referring to the automaker as Mazda from this point forward.

With engine displacement for kei cars capped at 360cc, Mazda had to find other ways to improve performance. MotorTrend writes that the company utilized the ‘gram strategy’ during the project. The R360 used a Plexiglass rear window, magnesium transmission housing and oil pan, and an alloy hood. Motor Trend also says that it weighed 838 pounds, or about 80 pounds lighter than the Subaru 360. It was introduced in May 1960. Mazda states that it had nearly 65 percent of the kei car market. Its 23,417 units were also good for 15 percent of the entire domestic automobile market. The company’s future in the passenger car market seemed promising. Just as the operation was getting off the ground, factors outside of Mazda’s control threatened its very independence.

Japan’s Ministry of International Trade and Industry, or MITI, wanted to strengthen the nation’s automotive industry in preparation for trade liberalization. MITI feared that foreign makes would overrun the domestic market. It tried to address the matter by building up the larger companies and getting rid of ‘excess competition’.

Nissan and Toyota, Japan’s two largest automakers, were losing market share to new entrants. In 1950, the two companies accounted for 83.3 percent of passenger car production. By 1955, it had fallen to 69 percent. And by 1960, it was down to 58.8 percent. MITI feared that increased competition would decrease the Big 2’s competitiveness.

To curb this excess competition, the body proposed a ‘3-group’ model. The first would be comprised of two conventional passenger car manufacturers. While specific brands weren’t named here, MITI certainly had Nissan and Toyota in mind. The second group would contain a handful of what the committee referred to as ‘specialty car builders.’ Vehicles of this type included luxury cars, mini diesels, and sports cars. Lastly, there would be two or three minicar producers. MITI developed these plans in 1960. If they came to fruition, then the company would lose its autonomy. It might even be merged with or absorbed by another company. Mazda needed a ‘technological character’ to justify its independence.

Identifying one would be difficult, as it had limited resources compared to the Japanese Big 2. Just when the situation seemed hopeless, Tsuneji Matsuda caught word of a radical new engine technology that had the potential to revolutionize the entire industry.

FELIX WANKEL EARLY DAYS

Felix Wankel took an unusual path to the automotive industry. His father died in World War I, and the inheritance that he left his family was decimated by inflation. This precarious financial situation prevented Felix from attending university. He worked at a bookshop to make ends meet and developed rotary technology on the side. Soon enough, he had enough money to set up his own shop. His early work primarily centered on rotary valves for motorcycle engines.

He was also a member of the Nazi Party. A Jalopnik article states that he had been involved with the group since 1923. Wankel was kicked out in 1931 and arrested two years later. He got his way out of jail and, in 1937, received a federally appointed factory. The man rejoined the party in 1940 and was kicked out for a second, final time in 1942. French authorities imprisoned him for his ties. The Drive states that Wankel was banned from research projects for a short time after his release.

ROTARY ENGINE BACKGROUND

Work on rotary endeavors wouldn’t resume until the early 1950s. He began working with NSU to develop a motorcycle engine with a rotary disc valve in December 1951. In 1956, motorcycles equipped with rotary piston engine superchargers were shipped to Bonneville and broke records in four categories.

During the early goings with NSU, Wankel discovered that the 4-stroke engine cycle could be done with a 3-lobed rotor. NSU didn’t have much interest in the idea, but he insisted. He even threatened to leave the company if they didn’t pursue it. NSU relented and agreed to share development costs.

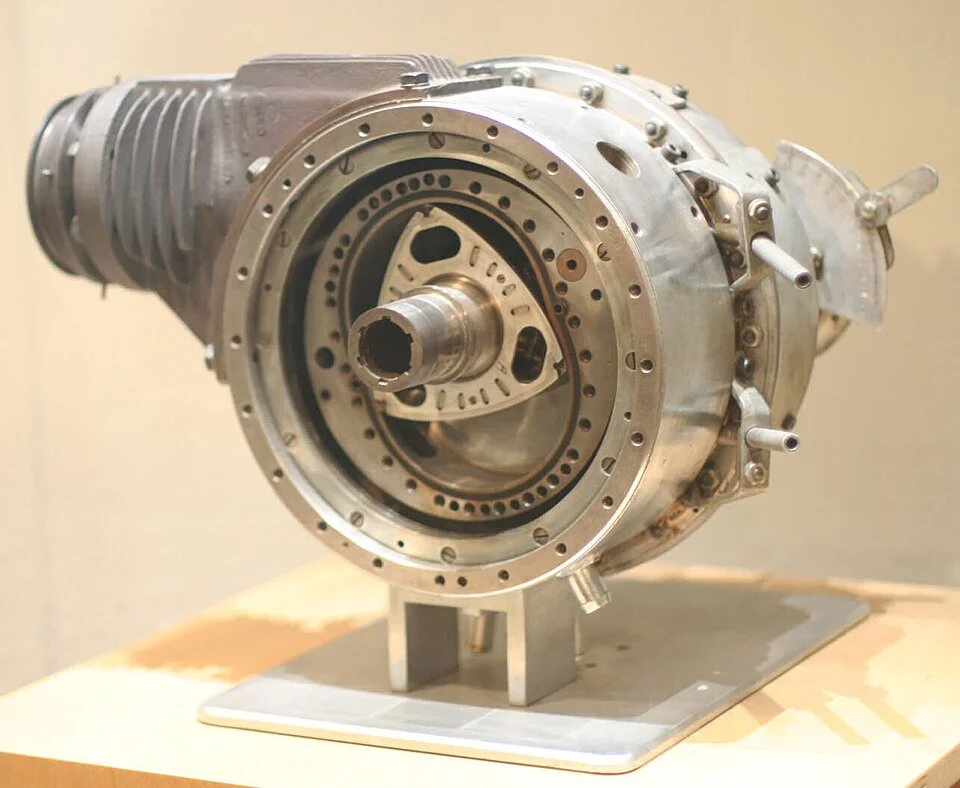

Rotary engines use a trochoidal rotor in place of conventional pistons. The rotor is set inside of a housing that has openings for spark plugs, water, and exhaust. There are three distinct openings at any time. During the intake stroke, the air-fuel mix enters the housing. The rotor compresses it and moves it toward the spark plugs, where it is ignited. Lastly, the rotor guides the gas out through the exhaust manifold. The cycle then begins again.

Rotary engines promised several advantages over their reciprocating piston counterparts. They had significantly fewer parts, which meant fewer potential points of failure. Thanks in part to their relatively simple construction, they were also lighter and more compact. Motor Trend writes that the rotor is placed on an eccentric shaft. For every three times the shaft turns, the rotor turns once. If, for instance, the engine is running at 9000 rpm, then the rotor itself would only spin at 3000 rpm. They did consume both oil and gas in greater quantities, though compared to the upsides that they presented, these seemed like minor drawbacks… for now (foreshadowing)

Wankel dubbed his initial design the DKM 53. It stood for Drehkolbenmotor, or rotary piston engine. 53 represented the year that he began working on it. In Sports Car Color History: Mazda RX-7, author John Matras writes that it ran ‘almost perfectly smooth’ and could run up to 25,000 rpm. It was also a hopelessly complex piece of machinery. The DKM had both a rotating inner and outer housing. Spark plug replacement also required complete engine disassembly.

At the same time, NSU engineers Dr. Walter Froede and Hanns Dieter Paschke worked on their own design. It was designated the KKM, or Kreiskolbenmotor. This one more closely resembled the rotary as we know it today, with a stationary housing and a rotor placed on an eccentric shaft. Froede and Paschke carried out their research in secret, as they feared that Wankel wouldn’t approve. Their fears were confirmed. He despised the KKM because it was a planetary motion, and not a pure rotary motion like his DKM. He even remarked that they had “…turned my thoroughbred into a plough horse.” NSU’s chairman didn’t see it that way. Work on the DKM ceased while KKM development carried on.

NSU decided to license its rotary engine technology to other companies. The first licensee approached them in May 1958: Curtiss-Wright, an aircraft builder. In October of that year, it paid $2 million for an exclusive license for North America. The deal also gave Curtiss-Wright the North American entitlement to sublicense the rotary.

MAZDA DISCOVERS THE ROTARY

Jujiro Matsuda stepped down in 1951, allowing his son Tsuneji to assume the presidency. The new boss first learned about the rotary engine in 1959. With the concerning developments in the domestic market, Tsuneji saw an opportunity to take the company in a new direction.

Mazda was not the only company interested in the technology. In The New Mazda RX-7 and Mazda Rotary Engine Sports Cars, author Jack Yamaguchi notes that over 100 firms sought a license, 34 of which were Japanese. Thankfully, NSU entertained Mada’s inquiry. Tsuneji and several other company representatives then visited its headquarters in Neckarsulm.

Matras writes:

“They were amazed by NSU engines on test stands and coins balanced on smoothly running engines, and impressed by NSU Prinz test cars with 25,000 miles of testing.”

NSU granted Mazda a license on October 12, 1960, the 40th anniversary of the company’s founding. The deal wasn’t officially approved by the Japanese government until July 1961. It cost the automaker 280,000,000, or $780,000, and allowed Mazda to use and sell rotary engines in Japan and Asia.

Soon after the agreement was finalized, the automaker formed the Rotary Engine Development Committee. This was a patchwork team comprised of members of the design, material research, production engineering, manufacturing, and test divisions. The deal also included some sample engines. Before these arrived in Hiroshima, engineers built test units based on the design of the KKM400. It was at this point that Mazda realized just how flawed the engine architecture truly was.

47 SAMURAI

Rotaries were touted for their smooth operation, but Mazda found that the prototype suffered from excessive vibration, even at idle. Engineers installed a rotary engine into a test vehicle. When turned on, it emitted thick, choking clouds of white smoke. Oil consumption was alarmingly high. Durability was no doubt its biggest flaw. Power dropped off considerably after 200 hours. Mazda stated that they’d even fail after an hour of operation. Any other company would seriously consider calling it quits at this point. Then again, most companies weren’t Mazda. It saw the technology as a chance to distinguish itself in an increasingly competitive automotive scene. The automaker went full speed ahead with its rotary ambitions, profits be damned.

If Mazda wanted to make it a reality, then it needed to shore up its research efforts. The patchwork approach it had taken thus far had turned in disappointing results. Larger automakers with more resources could take that same approach and make more progress on their rotary programs. To keep pace with its contemporaries, Mazda needed to establish a department wholly dedicated to. It did just that in April of 1963, when it founded the Rotary Engine Development Division. To head it up, Mazda looked to a young, brilliant engineer.

Kenichi Yamamoto may have been born in the city of Kumamoto, but he had Hiroshima blood in his veins. His family moved there when he was a child. In 1944, Yamamoto graduated from the University of Tokyo with an engineering degree. This led to a job at the Kawanishi Aircraft Company in Ibaraki Prefecture, roughly 60 miles north of the nation’s capital. He returned to his hometown after the war ended and found it in ruins. His mother survived the bombing, though his sister perished.

A nationwide aircraft ban enacted shortly after the war ended Yamamoto’s short-lived career in aviation. Desperate for work, he took a job on Mazda’s transmission assembly line in February 1946. While he was happy to have a source of income during this tumultuous period, he couldn’t help but feel like his years of education and training were going to waste. Instead of allowing his dilemma to consume him, he took advantage of the situation. Japanese Nostalgic Car states that he began studying transmission blueprints in his spare time. Management took note of his initiative and, in August 1947, transferred him to the engineering department.

From here, Yamamoto carved out a remarkable career for himself. He designed Mazda’s first overhead valve engine at the age of 25. In 1959, he became its became the deputy manager of the Engineering and Vehicle Design Division. He was involved in the development of some important products, such as the R360 and Carol. Yamamoto did not get to see the latter out to the end. At that critical juncture, Mazda transferred him to the rotary department.

This was a step down in his eyes. He went from spearheading critical production cars to trying to make something of a new technology. Its lackluster performance in the initial tests likely didn’t inspire much confidence in him, either. Nevertheless, he devoted himself entirely to his new duties. To fill out the ranks of the reorganized Rotary department, Yamamoto had to pull employees from other sections. At the end of the recruitment drive, it had 47 members, including himself. The team gathered at a Hiroshima restaurant in April. Yamamoto stood up to address his colleagues.

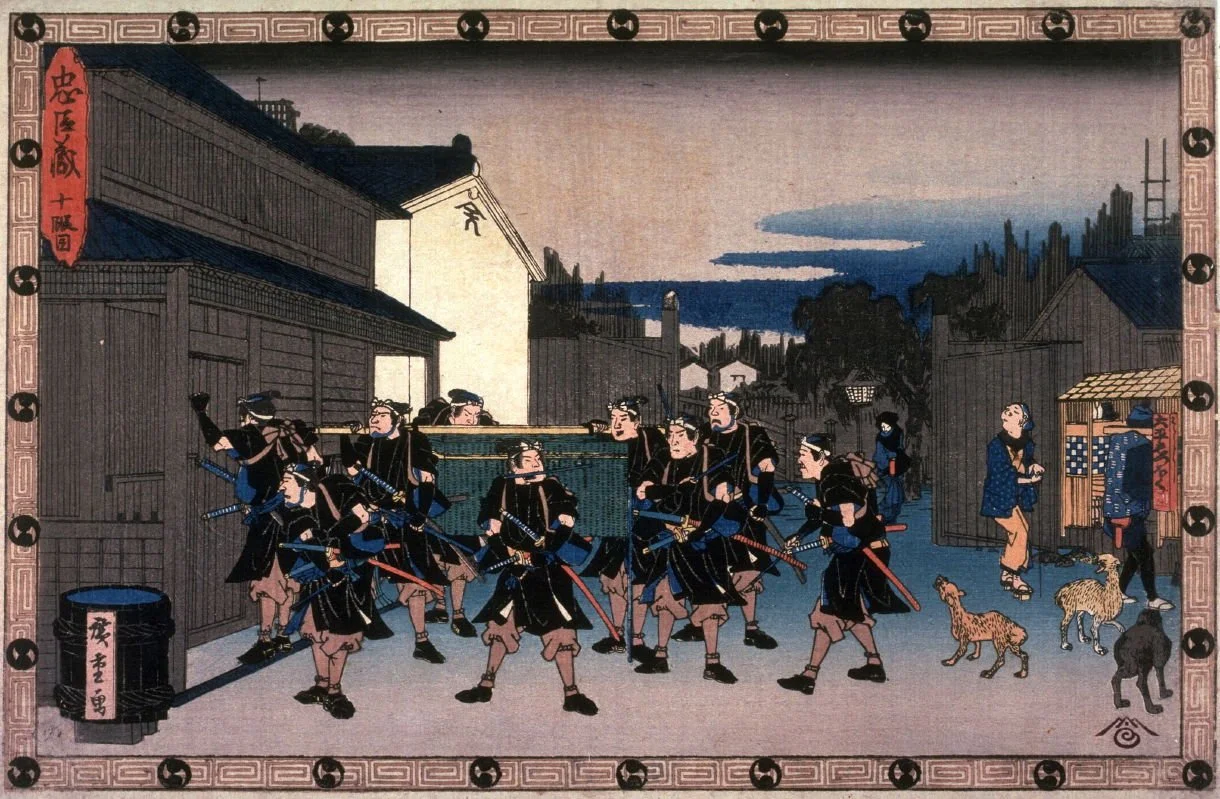

“I want us, the 47 Ronin, to think about the engine day and night until the rotary engine is completed. There may be difficult times, but when that happens, remember the hardships of the Ako Ronin.”

Few stories have resonated with the people of Japan more than that of the 47 Ronin. In preparation for a ceremony, Daimyos Asano Naganori and Kamei Korechika had to receive guidance on etiquette from court official Kira Yoshinaka. The pair were at odds from the very beginning. An article from HistoryTotallyNaked states that Kira was especially rude to the pair. He eased up on Kamei after receiving a bribe, but kept insulting Naganori. Tensions finally boiled over. Naganori, sick of the verbal abuse, pulled out a weapon and attacked Kira. The official walked away with only minor injuries. As for the young daimyo? Well…

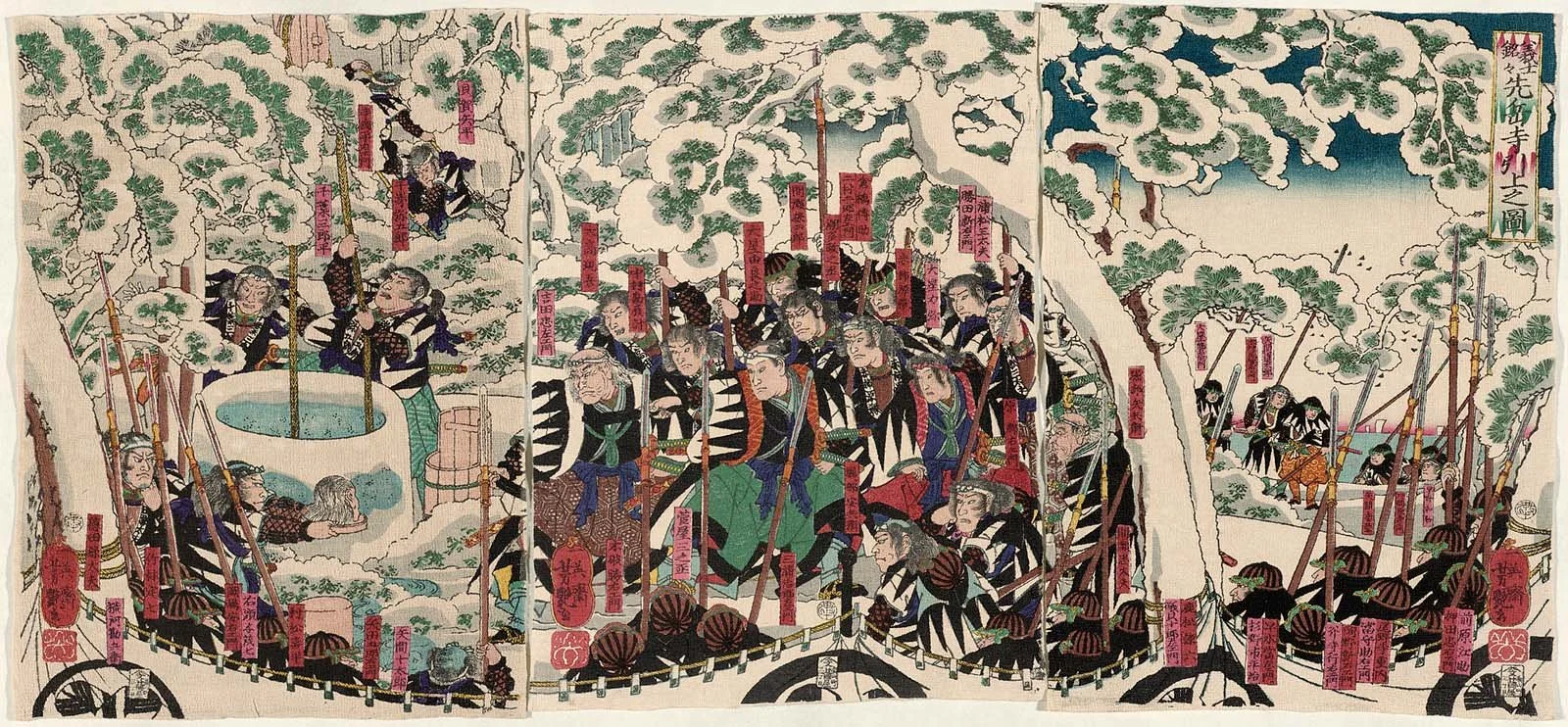

Drawing a blade in the Shogun’s castle was bad enough. Going after such a powerful figure all but sealed his fate. Naganori was ordered to commit seppuku. Additionally, his lands were seized, and his roughly 300 retainers lost their status and became ronin. Historian Luke S. Roberts defines them as “samurai without income, without a house, and of low social standing.” Most of Naganori’s men accepted their fate. 47 of them remained loyal to their master and sought revenge.

For over a year, the group kept a low profile while they devised their plan. On December 14, 1702, the 47 Ronin sprang into action. They infiltrated his compound, disposed of his men, and apprehended the man himself. Kira was given the chance to commit seppuku with the dagger that Naganori himself used. He couldn’t bring himself to do it. Oichi Kuranosuke Yoshio, Naganori’s chief retainer and leader of the 47 Ronin, took matters into his own hands. Finally, the group traveled to their master’s burial site. They washed Kira’s head at a nearby well and placed it on Naganori’s grave along with the dagger.

With their duty fulfilled, they turned themselves in. Bushido, the samurai code of conduct, stressed the importance of honor and loyalty. The 47 Ronin showcased these principles during their mission. Because of this, they were given the opportunity to commit seppuku. Afterwards, they were buried alongside Naganori. Over 250 years later, Mazda’s rotary department would embark on its own journey. Instead of restoring their master’s honor, the division worked to ensure the automaker’s independence.

DEVIL’S NAIL MARKS

Engineers primarily focused on improving engine durability. The rotor wore away at the inner surface of the housing, leaving behind ‘chatter marks’. They lowered compression and robbed the engine of power. The marks appeared after just 200 hours of testing. Both the NSU sample units and Mazda’s prototype motors suffered from the phenomenon. Employees became so annoyed by this issue that they began calling them ‘the devil’s nail marks’. The team found that they were caused by the apex seals vibrating against the housing. Some of the company’s research focused on reducing those unwanted vibrations. They subdued them by drilling horizontal and vertical holes in the apex seal. This significantly improved durability. Now, test engines could run for 300 hours before succumbing to the chatter market. While cross-hollow apex seals wouldn’t be installed on production rotaries, the situation did inspire the engineers to think outside the box.

Their attention then shifted to materials. Making the seals harder would make them more resistant to wear, but worsen the chatter mark issue. Using a softer substance would preserve the housing but make the seal less durable. NSU’s sample engine used cast-iron seals. Mazda experimented with a variety of materials, including plastic, resin, and even cow bone. Over 500 ideas were tried before they came to a solution: graphite. Evan Zabawski put Mazda’s thinking into perspective in his paper The Devil’s Fingernail Marks. Pencil lead is resistant to scratching yet glides across paper. The automaker got into contact with Nippon Carbon, which had been working with pyrolytic graphite.

It was resistant to impacts and could withstand extremely high temperatures. Nippon Carbon set up a lab to help Mazda address the apex seal issue. Using carbon-impregnated aluminum for the components gave them the necessary strength and scratch resistance for the job. A test engine with the new seals ran for a total of 672 hours and traveled for the equivalent of 90,720 kilometers. When engineers disassembled the motor, they found no signs of the dreaded chatter marks. Poor oil sealing resulted in increased oil consumption and produced the white smoke clouds. Mazda worked with the Nippon Piston Ring Company and the Nippon Oil Seal Company to create a special oil seal and lubricant.

THE FINISHING TOUCHES

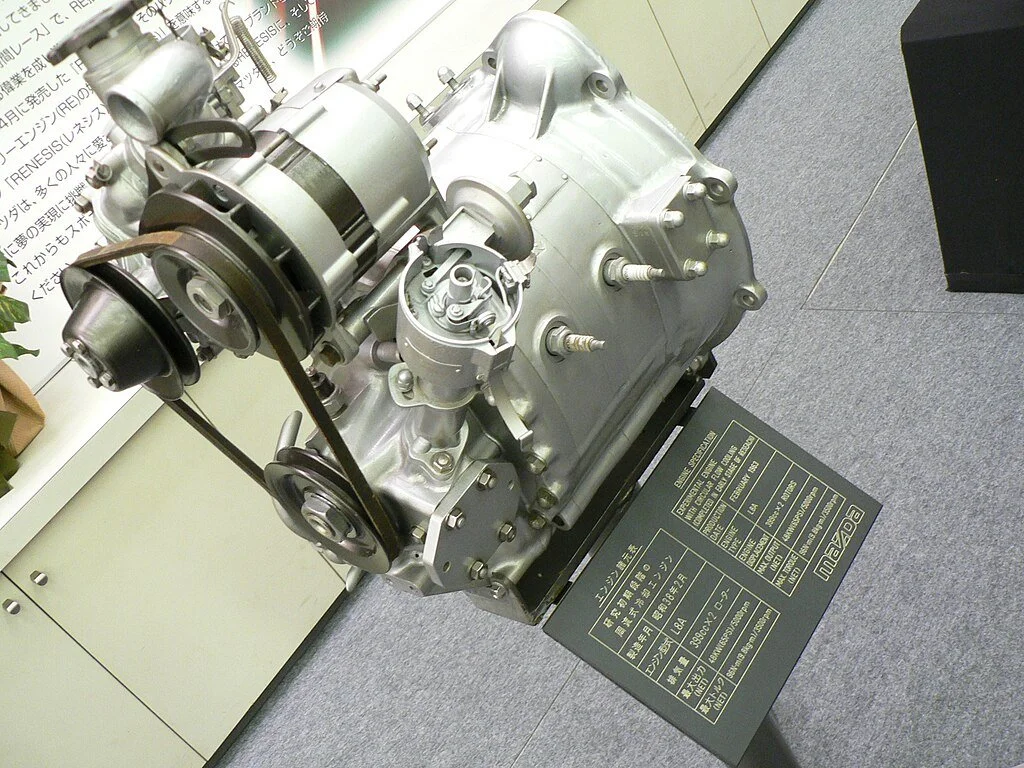

NSU’s prototype engine was a single rotor unit. Mazda found that motors in this vein suffered from excessive vibration at lower speeds and lacked low-end torque. It focused its research efforts on multi-rotor designs. A two-rotor setup emerged as the most sensible solution. Hagerty states that incorporating more than that would require either an awkwardly long eccentric shaft or an intricate coupling of two eccentric shafts. And whereas NSU’s engine made do with single spark plugs, Mazda’s engines would use two per chamber. The trailing spark plug would fire 5 to 15 degrees after the leading one to achieve more complete combustion.

The L8A rotary was finally completed in July 1963. It had a combined capacity of 798cc. Cranswick’s book notes its unusual two-stage intake system. When cruising, the engine used the side intake ports. When at full throttle, it would incorporate secondary and peripheral ports. Cranswick writes that the L8A suffered from low torque and poor idle smoothness. The reworked L10A just used side intake ports. Displacement also increased to 982cc.

The engine, while not perfect, hardly resembled the troubled NSU motor that arrived in Hiroshima several years earlier. Just a handful of automakers would ever be able to say that they developed a viable rotary engine. Only through Mazda’s efforts was it possible. As incredible an achievement as it was, it would only be one part of the company’s rotary revolution.

MAZDA COSMO DEVELOPMENT

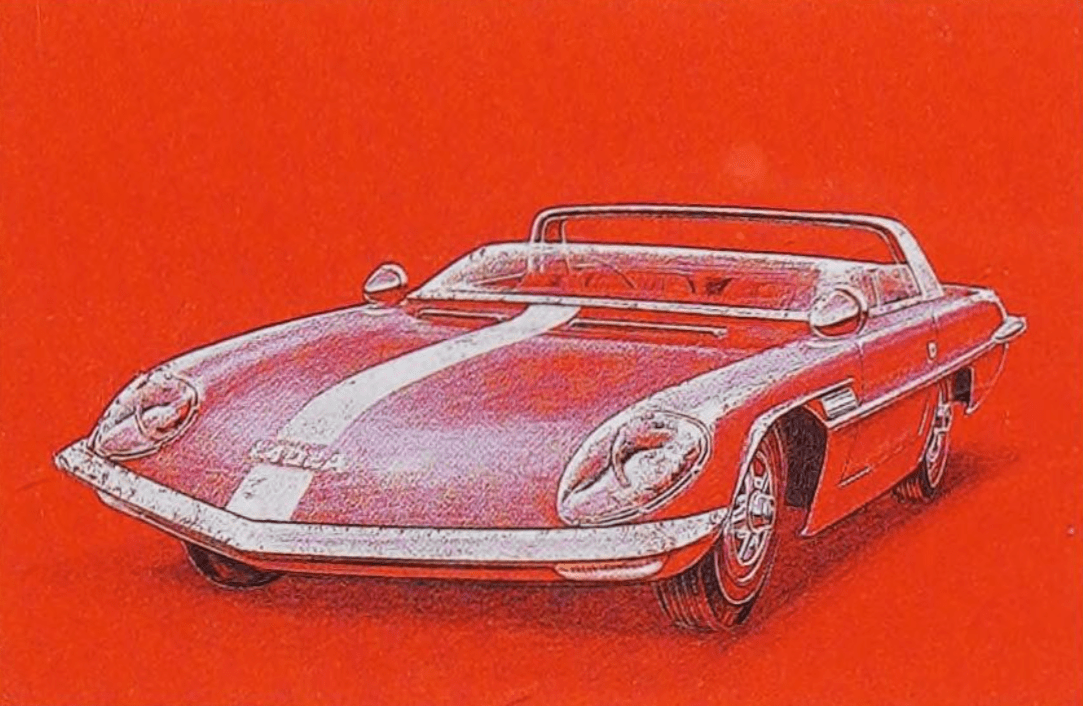

Mazda’s crown jewel wouldn’t be placed inside the R360, Carol, or Familia to start. Instead, the automaker would create a flagship sports coupe from the ground up for the purpose. Before installing it in its mainstream car, it wanted to see how the market would react to the technology in a niche, low-volume product. Debuting the rotary in a halo model would also create more public interest and bolster Mazda’s reputation both domestically and abroad. To this end, the automaker revised the deal with NSU to allow it to sell rotary-powered cars beyond Asia.

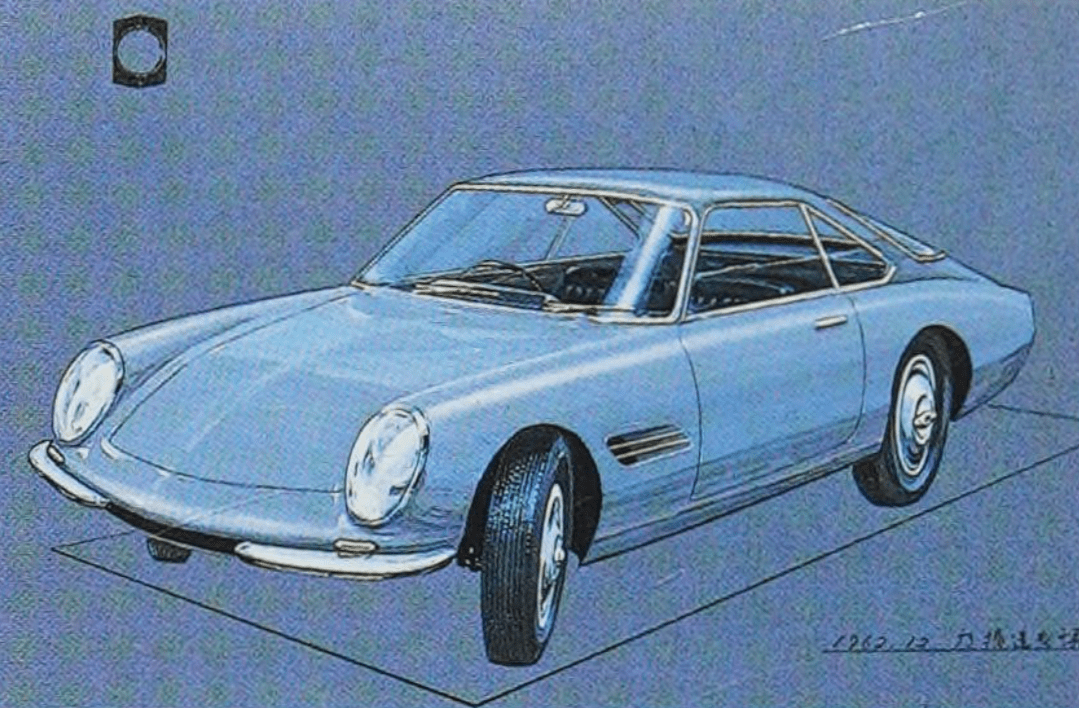

Work on the project got underway in December 1962. Early development sketches reveal the various directions in which designers wanted to take the car. This roadster features a wide body stripe as well as a distinctive Mazda wordmark. The company briefly considered a convertible but ultimately decided against it.

Various rear-end treatments were also tried. Most of the ones here show horizontal lights flanking a thin, long grille. One sports a novel light bar. It’s a slick look, though Yamaguchi writes that it would never be approved for sale in the Japanese market. Regulations specified “individual tail lights.”

Two proposals had progressed to the 1/5 scale model phase. One was styled by Heiji Kobayashi, Mazda’s first in-house designer. Previously, freelance industrial designer Jiro Kosugi styled its products. Kobayashi studied automotive design under the legendary Kenji Ekuan before joining the company. He’d already had a hand in the Carol by the time the rotary sports car project came through.

A 2017 Asahi Shimbun article details Kobayashi's unique disposition. He'd take time off from work whenever he could, particularly when a new foreign film would reach Japanese theaters. He'd stay home when it rained, claiming that he didn't own an umbrella. Kobayashi took unexcused absences after exhausting his sick days. When questioned, he said there wasn't anything wrong because he wasn't being paid for the time he wasn't home.

He competed with a colleague for the winning design. Both of their proposals reached the ⅕ scale model phase. The competing car took obvious influence from Italian designs, with upright headlights and a subtle profile curve. It almost looks like it came from an external styling house. Mazda had agreed to a deal with Bertone early in 1962, so the influence isn’t completely out of left field. It's well-sorted, though a bit underwhelming for Mazda's flagship sports car.

Kobayashi's proposal reflected his own interests and inspirations. Makoto Ishii, a clay modeler, recalled that he never read books about design. He had been fascinated with outer space. Ishii said that he studied it in detail and even drew pictures of space in his spare time. Kobayashi probably wasn't alone in this.

The space race between the United States and the Soviet Union was heating up in the mid-60s. It influenced furniture, dinnerware, architecture, and, yes, even automobile design. Mazda's sports car even borrowed its name from the world. Cosmo, the Italian word for space, announced to the world that the automaker was diving headfirst into the future. Tsuneji selected Kobayashi's forward-thinking proposal during the evaluation.

1963 TOKYO MOTOR SHOW

At the 1963 Tokyo Motor Show, Mazda took the wraps off its prototype rotary engine. Two examples were on hand: A 398cc single-rotor engine and a 796cc dual-rotor engine.

That wasn't all. The Cosmo may have been a few years out from seeing production, but that didn't stop the automaker from surprising those at the show. Prototypes were driven from Hiroshima to the event in Tokyo. This was actually a calculated move on Mazda's part to showcase the reliability of rotary technology. Of course, public perception of both Mazda and rotary engines would take a hit if the cars couldn't complete the journey.

The trip to Japan's capital was only one half of their excursion. Tsuneji Matsuda and members of the rotary department would drive the cars back to HQ, stopping at Mazda showrooms on the way. Fortunately, they returned without encountering any major issues.

Mazda officially unveiled it to the public at the following year's show. It was now known as the 802 Cosmo. There were a few changes to the design. The headlight housings round out instead of pointing forward, and familiar afterburner tail lights have been added. The tail has also been straightened out and lengthened considerably.

Mazda took the unusual step of turning 60 prototypes over to dealerships for testing purposes. They traveled a combined 375,000 test miles without encountering any mechanical failures. Yamaguchi says that there were a few accidents, though. Mazda also put the car through its paces at Miyoshi Proving Ground, which opened in 1965.

A third prototype featured a reworked fender vent. Now, the feature is color-keyed and pressed into the body. Additionally, the wraparound band had been replaced by a painted roof. In 1966, a fourth prototype was shown. Mazda finally unveiled the production Cosmo at the Hotel New Otani in Tokyo in front of 1,700 guests. In addition to the 6 display models, the automaker also brought 15 vehicles for testing.

The cars would be assembled at the company’s newly-completed plant in Ujina, Hiroshima. Matras wrote that the Cosmo wasn’t built on a conventional assembly line. Instead, the cars were pushed from station to station on dollies. This resembles the process that Honda would take with the NSX two decades later. Between 20-30 left the factory per month.

MAZDA COSMO HISTORY

The Mazda Cosmo 110S went on sale on May 30, 1967. It was not the first rotary-powered vehicle to hit the road. That honor went to the single-rotor NSU Spider, which had been available for purchase since 1964. Even still, the Cosmo does hold the distinction of being the first 2-rotor model to be released. NSU’s own 2-rotor car, the Ro80, wasn’t revealed until September.

It stickered at 1.48 million JPY, which converted to about $4,100. Road and Track wrote that it was a steep price to pay, comparing it to more accessible sports cars such as the Datsun 2000 ($2,360) and Nissan Silvia ($3,333). It was still cheaper than the Toyota 2000GT, which retailed for a staggering 2.38 million JPY in the Japanese market. In the United States, the Toyota had a starting price of $6,800.

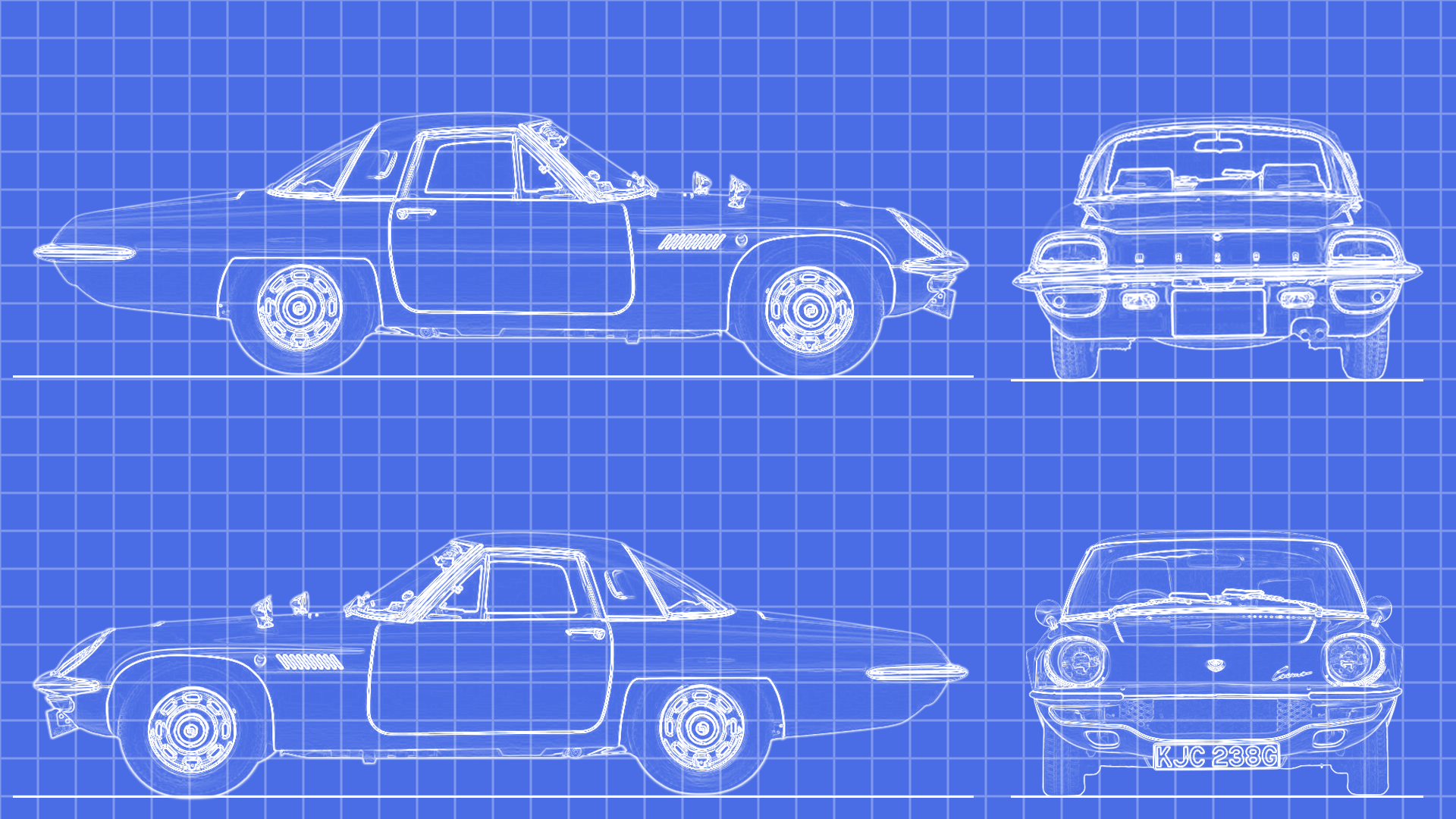

ENGINEERING

Powering the car was the 982cc L10A, which produced 110 horsepower and 100 lb/ft of torque. The 110 in its name references its power output. Mazda claimed a 0-62 time of 8.7 seconds, a quarter-mile time of 16.3 seconds, and a top speed of 115 miles an hour. Mated to this was a 4-speed manual transmission. The L10A Cosmo measured in at 4,140mm long (163’’) with a 2,200mm (86.6’’) wheelbase. It was also 1,595mm (62.8’’) wide and 1,165mm (45.9’’) tall. It tipped the scales at 940kg, or a touch under 2,100 pounds. Mazda installed disc brakes up front and drums at the back. Also of note was its suspension setup. The Cosmo had a fully independent front suspension and a De Dion configuration in the rear. Newswitch states that, due to the flat body, there was not enough space for a normal suspension.

Road and Track flew to Japan and took a Cosmo for a spin in December 1967. It came hot off the assembly line. The mechanic who delivered it to them asked them to keep it under 5000 rpm, as it had to be delivered to a customer later. The magazine didn’t quite take to the styling. Mazda had been showing it off here and there for about four years with only minor changes. By the time Road and Track got its hands on one, the once cutting-edge design began to feel dated. It remarked that its design had been conceived of in the late 50s and then forgotten about. Whoever wrote this is factually incorrect–the Cosmo is precious–but that’s neither here nor there.

The interior was also a mixed bag. While it was plush and well-equipped, testers found that the steering wheel was too low to be comfortably used by taller drivers. Heel-toeing was also tricky due to the pedal arrangement. Whatever faults the Cosmo had were more than made up for on the road. The engine was “dead smooth” and eagerly revved up to 7000rpm. Its clutch was equally agreeable. The suspension performed well on the urban streets of Tokyo but left something to be desired when pushed on winding roads. Body roll and squirrely tire behavior spoiled the Cosmo's cornering dynamics. Braking was strong, though. Road and Track wrote that it was “quite adequate if not phenomenal.” All in all, it found both the Cosmo and its rotary engine worthy of merit and eagerly awaited what the future held for the Hiroshima automaker.

L10B UPDATE

In July 1968, production shifted to the L10B Cosmo. Although the engine still had a displacement of 982cc, revised port timing increased output to 128 horsepower and 103 lb-ft.. It had a higher top speed of 124 miles per hour. It also gained a 5-speed gearbox. Mazda extended the wheelbase by 5.9 inches (to 92.5’’) but reduced overall length a touch. The reworked front clip featured a larger radiator grille flanked by a set of smaller intakes. Optional air conditioning also became available. The changes added 110 pounds to the curb weight and bumped the sticker price up to 1.58 million JPY.

1968 MARATHON DE LA ROUTE

Public perception surrounding rotary technology remained shaky despite Mazda’s efforts. Sure, they put out power that defied their diminutive dimensions, but were they as durable as piston engines? Mazda, eager to silence the doubters, entered the Cosmo into the Marathon de la Route 84 Hours. The automaker had a fair bit of competition experience. In the past, it raced the R360, Carol, and Familia in events all across Asia.

The Marathon de la Route was a different beat altogether. Over the course of three and a half days, contestants would have to navigate through the notoriously grueling Nurburgring. Japanese Nostalgic Car states that, in 1965, only 24 of the 35 entrants actually crossed the finish line. In 1967, just 13 of 43 participants finished the race. Even the course vehicle crashed. Mazda needed to have a strong showing in the event. Anything less would undermine its efforts.

Two manufacturer-backed teams would be entered. An all-Japanese crew comprised of Nobuo Koga, Yoshimi Katayama, and Masami Katakura would pilot the #18 car. The #19 car, meanwhile, would be driven by three Belgians in Jean-Pierre Ackermans, Yves Deprez, and Leon Last.

The cars used modified versions of the L10A. Combination side and peripheral ports may not have been in keeping with the production cars, but they could make the rotary more potent on the race track. Output increased to 130 horsepower. Mazda also extended the wheelbase, added power brakes, and enlarged the grille opening. Testing took place at Miyoshi Proving Ground and Suzuka Raceway. Japanese Nostalgic Car says that the cars were so loud that nearby farmers complained that their cows had stopped producing milk.

On August 21, 51 cars lined up on the starting grid. The unproven Mazdas would have to hold their own against the likes of Porsche, Lancia, and BMW, makes which had long been established in the competition space. Whatever preconceptions the spectators may have had were shattered, as the Cosmos jumped out to fourth and fifth place in the early goings of the race. They fended off their rivals and held onto their positions late into the event. Both cars seemed destined to cross the finish line intact. In the 82nd hour, the #18 car suffered a broken rear axle. Katayama lost control of the car as it flew off the road. Fortunately, he was able to walk away from the carnage. The #19 car finished fourth overall. Although Mazda didn’t win the event, the strong finish proved that rotary engines could withstand the rigours of competition.

MITI’s plan to consolidate the domestic motor industry never quite came to fruition. The concept, no matter what form it took, couldn’t get the required support from automakers or legislators. Instead of trying to force their hand, MITI would instead incentivize mergers with administrative assistance and loan programs. The financially troubled Prince Motor Company was but one manufacturer to be involved in a tie-up during this period. The head of Sumimoto Bank tried to organize a merger between it and Mazda. It was the principal bank for both automakers, so the pairing wasn’t completely out of left field. Mazda rebuffed them. The company valued its independence.

MITI got involved around this time. Officials spoke with Toyota before settling into negotiations with Nissan. Their deal became official on August 1, 1966. An equal merger this was not. Nissan completely absorbed its partner. Driven to Write notes that the outgoing Glorias and Skylines were ‘double-badged.’ Their successors, released in 1967 and 1968, respectively, did away with the Prince emblems. Toyota made deals as well, bringing Hino and Daihatsu under its umbrella. A proposed merger would have seen Mitsubishi, Isuzu, and Fuji Heavy Industries join forces to create an entity that Genther says could have challenged the Big 2. The deal never got off the ground.

Mazda entered the 1970s with newfound confidence. Not only did it manage to remain independent, but it also established itself as Japan’s third leading automaker. The range-topping Cosmo also served its purpose admirably. Production ended in September 1972. 343 L10As and 1,176 L10B had left the factory, bringing the total number to 1,519. It strengthened Mazda’s reputation and signaled an end to the company’s Batanko days. Most importantly, the automaker found its identity in the rotary engine. In a time of crisis, the entire company rallied together toward a singular goal. By making it viable, it showed the world and itself what it was truly capable of. The Cosmo was just the beginning of Mazda’s rotary revolution!