Honda’s CVCC Engine Was A REVELATION

INTRODUCTION

Honda embraced the challenge of car manufacturing after a dominant reign in the world of motorcycles. The T360 kei truck and the S500 roadster were unveiled at the 1963 Tokyo Motor Show. By the middle of the decade, their automotive operations flashed glimmers of what could be. It leaned heavily on the sales of commercial vehicles in the early days. Cars of this variety included the T360 as well as the S-derived L and P-lines. They sold about 44,000 in 1965 and about 55,000 in 1966.

The S-series, on the other hand, could be seen as a bit of a disappointment when you consider that it was pitched as a commuter car. Sales were a bit over 1,300 across 1963 and 1964. This number improved as the updated S600 hit the market, with sales of 9,000 and 3,000 in the years following. The majority of cars sold in Japan in the early to mid-60s were commercial vehicles, so the reception wasn't as cold as it initially seemed.

The combined efforts of their commercial and consumer lineups were enough to secure Honda a 2.5 percent share of the market. They weren't major players in the space quite yet, but it was a solid foundation that could be built upon. Honda did just that when they introduced the N360 kei car in 1967.

Production skyrocketed to 87,000 units that year, then to 187,000 in 1968, and then finally to 233,000 in 1969. Their share of the market also increased, going from 6.9 percent the year the car was introduced to 10.7 percent. And this was just the beginning.

The Japanese automotive marketplace was coming into its own in the late 1960s. Its highway system went from being primarily composed of unpaved roads to becoming a vital link between prefectures. This made the automobile a more attractive proposition to the people of Japan, who were becoming more affluent as national income levels increased.

In 1963, there were about 900,000 registered vehicles in the country. by the end of the decade, this number had balloned to over 5,000,000. Other automakers were scrambling to meet the demand. The country's stock of 3 and 4-wheeled vehicles rose from 5,000,000 to 14,000,000

Honda had an opportunity to dramatically scale up its automotive operations. First, they wanted to expand their model lineup. They had the best-selling kei car in the segment, but car buyers were expecting more space and a higher level of refinement in their vehicles. Kei cars were earning a negative connotation among car buyers. They gained the nickname of gamansha, or patience cars, to be driven by those that needed to wait until they could afford something better. Other makes had large model ranges that could satisfy the demands of the market. Toyota sold 8 cars ranging from the compact Corolla to the full-size Century while Nissan marketed five of its own.

So Honda got to work expanding their own lineup. The H1300 had the potential to cement the company as a legitimate automaker. It was well-received upon its debut, but the car’s momentum was undone by a myriad of issues, most of which stemmed from its air-cooled engine. The H was heavy, expensive, inefficient, and suffered from unbalanced driving dynamics. It was a flop, and just like that, Honda’s future success in the auto industry went from a near-certainty to a complete unknown.

They didn’t have the bottomless coffers of the Japanese Big Two. Cars were significantly more expensive to develop than motorcycles, and the effects of creating something that didn’t resonate with the market were magnified. This set their automotive operations back years, and the company would have to plan their next move very carefully to avoid flaming out of the industry altogether. And then, in an instant, the automotive industry changed forever.

CLEAN AIR ACT

The seeds for widespread environmental regulation in the United States were actually planted during Detroit’s heyday, when General Motors, Ford, and Chrysler cast any semblance of rationality to the wind. The Air Pollution Act of 1955 didn’t actually set any rules in place on a federal level. Rather, it freed up $5,000,000 for research and placed the burden of regulation upon state and local governments.

It wasn’t until the 1963 Clean Air Act that pollution became subject to national statutes. The bill allocated tens of millions of dollars more to research and established the Public Health Service within the Department of Health, Education, and Welfare. This precursor to the Environmental Protection Agency gave D.C. its first bit of influence in this field, as the wing had the authority to take legal action against industries in certain cases. Congress amended the bill in 1965 with the Motor Vehicle Air Pollution Act. This authorized the government to set emissions standards beginning with the 1968 model year.

And through its research, it determined that whatever regulations were going to be established needed to take effect as soon as possible. A study in 1966 estimated that, out of a total of 142 million tons of pollutants, 86 million tons, or about 60 percent, could be traced back to automobiles. In densely populated urban areas such as Los Angeles, this number was closer to 90 percent. All of this foreshadowed the most extreme environmental legislation the industry had ever seen.

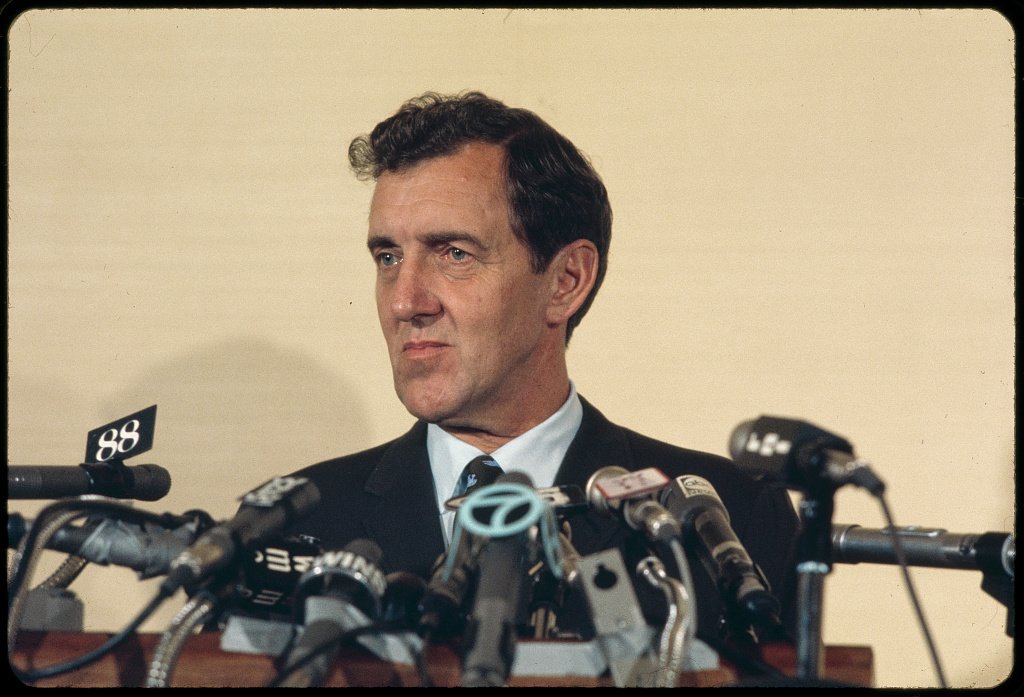

The year is 1970. Edmund Muskie, A senator from Maine, proposed a major revision to the Clean Air Act. The plan contained radical changes to many sectors and had the automotive industry directly in its sights. The motion detailed strict emissions standards that would go into effect in the near future.

Cars were required to emit one-tenth of their carbon monoxide and hydrocarbons by 1975. Those built in 1976 also needed to produce a tenth of their current nitrogen oxide levels. Automakers thought that it would be impossible to meet these specifications in such a short amount of time. They threw a fuss, but after the bill passed through the House of Representatives and the Senate, President Richard Nixon signed the Clean Air Act into law on December 31st, 1970.

Japan wasn’t far behind in enacting their own standards. Their ministry of transport began enforcing restrictions on vehicle emissions as far back as 1966. The Basic Law for Environmental Control went into effect in 1967 and in 1968 the Air Pollution Control Act was signed into law. Future studies showed the importance of such legislation. A survey in 1970 found that the lead levels in the blood in Shinjuku were unusually high. Many pointed to the lead that was used to formulate gasoline as the main culprit. Additionally, about 50,000 people were negatively affected by the staggering amount of pollution.

Tokyo’s air pollution had also surpassed New York’s and was second only to Los Angeles. A 1972 study determined that a large majority of it came from cars. They were responsible for about 33 percent of the nitrous oxide, about half of the hydrocarbons, and as much as 90 percent of the total carbon monoxide discharge. This motivated the ministry of transportation to enact strict emissions standards of their own in 1972, which would affect cars built after April of 1975.

CREATION OF THE AP LAB

Honda, being the auto industry’s newest entrant, seemed likely to be the first of them to bow out of the market. They’d been building cars for less than a decade and their most recent product was an absolute failure. Finding a way to meet the looming emissions guidelines would also cost a fortune. Most companies in their predicament would have cut their losses at this point. Honda was also the largest motorcycle company in the world, and they could use that money to help maintain their market position. For everything that was going against them, they did have one thing that no other company could claim; an autonomous research and development subsidiary.

Honda’s design and engineering divisions had historically been scattered throughout their factories. This spreadfire approach complemented their scrappy nature and resulted in products such as the Benly and Juno. Company leadership sought a way to streamline the development process as Honda grew in size.

At the same time, company founders Soichiro Honda and Takeo Fujisawa saw an opportunity to bolster its R&D efforts. They reasoned that the Detroit Three were so successful because they invested staggering amounts of money into research and development. They found that American companies put as much as three percent of their revenues back into the development cycle, which is a massive sum for enterprises at that scale. This, in turn, allowed them to quickly create products that were right in line with consumer demands. Soichiro brought up another point when he said:

“Had we left research in the middle of Honda Giken Kogyo, it would have been treated as a step-child, for that company’s purpose is the pursuit of profits. Since good research cannot be treated as simply as an appendage of manufacturing, I decided that it would have to be a separate, distinct operation in our family companies.”

The pair thought an independent R&D center would be integral to Honda's outlook in the future, though they would have to convince the section managers of its importance if it was to become a reality. Fujisawa held meetings and wrote articles in the company newsletter to get them on his side, but they still weren't swayed.

Then, in May of 1960, Fujisawa organized a critical gathering of directors at the Oiso Prince Hotel. He was so set on the division that he considered resigning if they couldn’t come to an agreement right then and there. The proceedings lasted two days, but in the end, the managers declined to pursue the matter.

Before the room cleared out, Fujisawa emphasized the importance of the R&D center. The company relied heavily on the engineering mastery of Soichiro Honda. It had been successful thus far, but it couldn’t be this way forever. The R&D center would allow for dozens of engineers to work in an environment that emphasised creativity. They wouldn’t have to buckle to market fads or cash-conscious corporate bureaucrats. In a way, it would allow the company to maintain its unique structure, with the parent company, i.e Takeo Fujisawa, focusing on the financial side of things and the R&D center, i.e. Soichiro Honda, working on the company’s next great innovation.

This last-ditch effort turned the tides in his favor. Honda R&D Co. opened on July 1st, 1960 with Soichiro serving as its president. The parent company didn’t wait to invest in it. In 1965, only a few years after it was established, Honda put about 2.5 percent of the funds gained through their total sales back into research and development, which was right in line with the average of American automakers. For comparison’s sake, Toyota and Nissan averaged about 1.94 percent while the Detroit Three as a collective sat at around 3 percent. The department proved its value right away, spearheading the development of Honda’s passenger cars and getting their Formula 1 campaign off the ground, but meeting the Muskie regs was bound to be its most critical undertaking.

The department actually began researching pollution years before the Muskie regs became a reality. In 1965, engine performance group leader Shizuo Yagi organized a 10-person Air Pollution Research Group. It began by collecting data on emissions as well as regulation trends in both Japan and The United States. The group also regularly held meetings to share their findings with other departments. It was at one of these meetings that Yagi, R&D director Taksu Date, and engineer Kazuo Nakagawa decided to push for a dedicated lab for air pollution research.

This would have to wait. The mid-60s were an especially hectic time for Honda. They were developing a mainstream kei car, revising the S-line for overseas markets, and putting the finishing touches on the RA271. These projects had some kind of tangible payoff in the near future for Honda. They weren’t sure how emissions research could benefit them yet, so the pollution lab was set on the backburner.

R&D members performed more research on their own. In June of 1966, the Japan Automobile Manufacturers Association organized a committee to tour the US in order to study auto emissions. Yagi was one of its members and thought that it would be invaluable to his research. The three leading voices in favor of the lab pleaded with R&D general manager Hideo Sugiura to allow him to make the trip. He obliged. The group visited 23 research labs during the month-long excursion. The facilities of the Detroit Three were obvious stops, but they also went to those of government agencies and universities.

Not long after this, the Air Pollution Control Research Lab (henceforth AP Lab) was officially launched. And it wasn’t a moment too soon. Environmental legislation began going into effect around this time, and the AP Lab began working on ways to curb pollution. That early enthusiasm that the trio had never subsided, though the team found itself stumbling along the way. Honda was fresh off the heels of their victory at the Isle of Man Tourist Trophy and in the midst of their F1 run. Going from drawing power from their engines as any cost to controlling emissions was a jarring change of pace. Taksu Date went through some of the difficulties, saying:

”We had no answer as to what caused air pollution, back then. "All we had was a device that measured carbon monoxide. We even had to ask what NOx and HC were, since in Japan there were no devices available to measure them. At first, we used something called a gas chromatograph to see the color reaction when exhaust gas drawn into a syringe was treated with chemical reagent. With this method, however, the engine condition would change while we were taking measurements. We simply were not able to apply our findings."

In this early phase of their research, they also explored a piece of technology that found a place in the labs of automakers the world over: the catalytic converter.

CATALYTIC CONVERTERS

You’d assume that the catalytic converter was a relatively new phenomenon with the automotive industry’s sudden interest in them. It was actually decades in the making. French inventor Eugene Houdry first patented the catalytic converter in 1952. It’s basically a chamber between the engine and exhaust system that contains platinum, palladium, and rhodium. Modern systems arrange these metals in a honeycomb pattern, but early layouts used ceramic pebbles coated with them.

There are two phases in the process. In the reduction catalyst, nitrogen oxide molecules come into contact with the metals. The resulting chemical reaction breaks the compound down into less harmful nitrogen and oxygen molecules. During the oxidation catalyst, the carbon monoxide and hydrocarbons react with oxygen molecules to create carbon dioxide and water vapor. All of this resulted in significantly reduced emissions.

This appeared to be exactly what the automotive industry needed. Why did they only begin gaining steam in the late 60s and early 70s? There were a few reasons for the late adoption. Gasoline back then was treated with lead to reduce engine knock and increase its octane rating. It also coats the metals within the catalytic converter, rendering the device completely useless. The push for white gas, or gas without lead, began picking up steam, which finally made their application in the automotive industry a possibility.

Houdry also originally designed catalytic converters to be used in places such as factories where they wouldn’t move around very much. Automobiles weren’t an ideal environment. The constant movement and vibration wore down the beads inside of the chamber. They would lose their effectiveness over time or even burn to a crisp. Honda found that a higher air-fuel mixture would be needed in order to ensure thorough burning of the materials, which decreased fuel economy. They were also concerned about their long-term effects. In the book Honda Motor: The Men, The Management, The Machines, the company said:

“The human body is made up of mineral water, the composition of which is similar to that of sea water. It does not contain heavy metals. What would happen if catalytic converters were installed in a large number of automobiles, emitting platinum, palladium, and other heavy metals that would then enter human bodies? There are too many unknowns. At our company, let us try to clean up the exhaust gases inside the engine itself without relying on catalytic converters.”

So Catalytic converters we’re out of the question. Honda obviously saw them as a short-term fix and wanted to find a more permanent solution for the Muskie regs. Some in the AP Lab thought that the internal combustion engine itself was at the root of the issue. The company could hedge their bets on a completely new type of power plant.

Honda wasn’t alone in this line of thinking. Automakers all over the world were spending millions of dollars developing experimental engine technology. The opinion around the industry was that the rotary engine would be the key to meeting future emissions regulations.

A conventional engine uses pistons to compress an air fuel mixture in each of the cylinders. This is then ignited by the spark plug, creating an explosion that forces the piston downward and thus creates the energy needed to rotate the towers. Conversely, everything in a rotary engine takes place within a single chamber. Air and fuel are pulled into it and compressed by a triangular rotor that spins in a circular loop. Rotary engines were light, compact, quiet, and had fewer moving parts than conventional engines. They were hamstrung by poor gas mileage and oil life, but companies did find that they’d be able to meet the Muskie regs without the use of catalytic converters. Nitrogen oxide levels were already below the threshold and carbon monoxide and hydrocarbon levels could be lowered with the use of a thermal reactor.

There was an immense amount of interest in the idea. Mazda was the leader in this regard. They were developing one of their own and had also entered negotiations to supply Toyota with them. Nissan, Ford, and General Motors were also experimenting with the technology. GM paid $50,000,000 just for the license. Actually bringing one to market was sure to cost tens of millions more, so this shows just how much faith the company had in the idea. Ford, meanwhile, was struggling in their rotary-engine endeavors. They licensed the tech from TWO German companies, as development on their own was coming along much slower than they were anticipating.

Honda explored the concept but found that there were too many drawbacks for them to seriously pursue it. You see, there were several requirements that a potential solution would have to fulfill before the company would devote a substantial amount of resources to it. It would need to be low polluting and have good fuel economy, be reliable and easy to maintain, have the potential to be mass-producible in the near future, and could provide Honda the chance to license the technology to other companies. We’ll delve into that last point a bit later.

Generally speaking, rotary engines suffer from poor gas mileage and also need constant oil changes. The triangular rotor requires special machinery to produce. It would cost millions of dollars just to get the tooling in place. And this would only be after years of engineering work and real-world testing.

It also didn’t help that the idea hadn’t been successfully implemented up to that point. NSU used them in the Spider and Ro80 to disastrous results. The components were put under a massive amount of stress and failed. It wasn’t uncommon for the engines to completely fail after just 15,000 miles. Then the company had to replace them, which put them in a financially precarious position and contributed to their eventual downfall. Honda didn’t want history to repeat itself, so they dropped the idea and looked to other options.

Diesels were on the other side of the spectrum. Honda thought that, with a bit of work, they could meet the future emission standards. The diesel engine was also a proven layout and could be easily mass-produced with their existing tooling. As with the rotary, the negatives could not be overlooked. Generally speaking, they were heavier, dirtier, harsher, and noisier than their gasoline counterparts. Honda felt that whatever could be gained through emissions reduction wasn’t worth the compromises that would have had to be made to day-to-day livability.

These weren’t all of the ideas that the AP Lab pursued. They examined gas turbines and Stirling engines as well as alcohol and hydrogen-based fuels. They were all abandoned because of some combination of long development time, prohibitively expensive tooling, and questionable future prospects. It was during this phase of their research that the AP Lab came to an epiphany.

No automaker had the technology nor the engineering manpower to meet the Muskie regs at the present moment. This meant that they were all at the starting line along with Honda. At the same time, they also noticed that all of their competitors were exploring similar avenues. If Honda were to simply follow their lead, then they wouldn’t come any closer to making a breakthrough. They couldn’t afford to squander this once-in-a-lifetime opportunity. So while engineers from other companies looked to the same far-forward concepts, the AP Lab looked to the past.

LINK TO THE PAST

Taksu Date thought Honda would be better off getting the most out of internal combustion engines. And the best way to reduce the amount of the pollutants in question would be to optimize the air-fuel ratio. There exists an ideal ratio of air and fuel that will burn away both and leave behind no excess air known as the stoichiometric mixture. For petrol engines, this is 14.7:1. 14.7 grams of air are required for every one gram of fuel. Cars use a “rich” mixture, or one that is higher in fuel, because lean mixtures tend to cause unstable combustion. On the flip side. Rich mixtures result in lower gas mileage. Date sought stable combustion that was either near to or lower in fuel than the stoichiometric mixture.

R&D performed a variety of experiments to achieve their desired fuel mix. They tried heating the mixture, increasing the gas movement throughout the cylinder, increasing the ignition energy, and achieving multiple ignitions with several spark plugs at once, but none of this went anywhere.

Then Date proposed something else. They could create two mixtures - one very lean mixture and another very rich mixture - and combine them somehow to achieve a balanced result in the end.

This actually wasn't a new concept. Powerplants of this variety even had a name: stratified charge engines.

The idea stretched back to the early 1900s. British engineer Sir Harry Ricardo wanted to solve two issues that were plaguing motors of the day: slow, incomplete combustion and engine knock. A rich air-fuel mixture would be easily ignited near the spark plug. The remainder of the cylinder would be filled with a leaner mix. Researh on gasoline stratified-charge engines stalled for the next several decades.

Texaco had been developing their own version of this since at least the late 1940s called the Texaco Controlled Combustion System (or TCCS). Their research in this field culminated with them earning a contract with the U.S. Army in the early 60s. They sought to convert the L-141 engine into a single-cylinder stratified charge motor, as they thought it could provide increased fuel economy and multi-fuel capability. In 1973, Texaco built an experimental TCCS engine fitted with a catalytic converter that could meet the 1976 emissions standards.

The most prominent stratified charge engine that was in development during this time was Ford's PROCO engine. The name was short for "programmed combustion" and it relied on a computer-controlled fuel injector to time the spark plugs just before the fuel and air mixed. Work on the engine commenced in the late 50s and by 1960 they had created a successful laboratory engine. Then Ford ran into a myriad of issues. PROCO suffered from severe durability issues, increased fuel consumption and nitrous oxide emissions, and noticeable power loss. They were hopeful that it would eventually see production, but even by their own estimations, it wouldn’t be ready until at least 1980.

The most successful stratified charge engine up to this point was the Nilov engine from Russia. Work on this motor began in the 1950s and it was developed as an alternative to large, inefficient marine diesel engines. It wasn’t designed with automobiles in mind, but a scaled-down version of this was placed into the GAZ-3102 in the 80s.

HONDA DEVELOPS THE CVCC

Date’s initial idea was to attach an auxiliary combustion chamber to the main one. The former would receive a rich mixture while the latter would receive a lean mixture.

The R&D department established a special task force in 1969 to explore the idea further. The SCE team began experimenting with a GD90 Diesel engine while their N600-based test engine was under development. That diesel utilized a pre-chamber that was similar to the one that they hoped to develop. They installed a spark plug and gasoline injection nozzle in the pre-chamber, remodeling the engine to allow the pressure ratio to be adjusted to their liking. These tests took place between December of 1969 and February of 1970, and in that span the engine showed signs of having stable lean combustion.

The trial N600 engine was finished in January of 1970. Their focus then shifted to tweaking the geometry and conditions of the pre-chamber in order to achieve their desired combustion characteristics. Researchers also studied how the connection between the pre-chamber and the main cylinder affected the burn.

In their efforts to meet the emissions requirements, the team also explored water-cooled engines. This is of significance because Honda was one of the few companies still holding firm on air-cooled engines. The AP Lab didn't have any of their own to work with, so they needed to perform their tests on units from other companies. This did have an unexpected benefit. Their research would be proven to work with technology from other automakers. this would strengthen Honda's case when it came time to license the technology to others.

Blueprints for the engine were drawn, and the first prototype engine was completed a mere two months after that. Honda built 100 more of them and installed them in Nissan Sunny bodies for further testing. This was a few years out from the release of the Civic. They didn't have a car of that size in their range, so they had to look to one of their competitors. It was then a matter of tweaking the main chamber, pre-chamber, and fuel supply method until they found a formula that worked.

WHAT’S IN A NAME

Honda was acutely aware of the importance of this project. The sheer amount of resources and manpower the company put into it best illustrates this point. In 1970, both Toyota and Nissan spent $22,000,000 on anti-pollution research. Toyota also had at least 280 working in that field. Honda, by far the smallest car manufacturer of the three, poured a staggering $25,000,000 on the stratified engine technology and had assigned 580 employees to work on some aspect of it. There was still much work to be done before it saw widespread production, but, partway through development, the stratified engine technology was showing encouraging signs.

Their early research was so encouraging, in fact, that Soichiro Honda arranged a press conference to officially unveil it. The decision to publicly announce a technology that was still being researched seems baffling on the surface, but Yagi says that there was a method to the madness.

"Mr. Honda told us, ‘If I asked you guys when it would be completed, you’d never tell me that you had it completed to a tee. The company would go bankrupt before you’d say that.’ So, he took a chance, announcing it publicly once it was clear that the prospect for such an engine existed.

"As we say at Honda, it was Mr. Honda’s habit to ‘leave you upstairs and take down the ladder.’ By making a public announcement on the CVCC, I believe he aimed to build up our morale. In the process, he could promote our work in research and development."

Yagi, Date, and Nakagawa thought it would be wise to give the engine a name so that it would resonate with the public more effectively. The trio rushed to the reception room to brainstorm ideas. Date recalls:

"Even though we had determined the possibility, we were still in the middle of research. "In fact, we were still processing our patent application. This meant that the name of the engine had to be contrived carefully, in order that the public announcement not reveal even a part of its structure. And we were as yet undecided about how to supply fuel. We got our heads together to come up with a name that was unique; something that had a bit of punch to it."

After some time, they finally had a name. Compound Vortex Controlled Combustion, or CVCC. Compound refers to the relationship between the main and auxiliary chambers. Vortex represents the ignition that travels from the prechamber to the main chamber. The action resembles a swirl, or vortex, and has the ability to speed up the combustion process. Lastly, controlled combustion refers to the engine’s ability to control the speed and temperature of combustion.

The press conference was held in February of 1971. Here, the company officially announced that it was developing a technology that could meet the emission regulation standards for 1975. Soichiro also said that it would be commercially produced in 1973, which gave the perfectionists at R&D a firm deadline.

HOW DOES CVCC WORK?

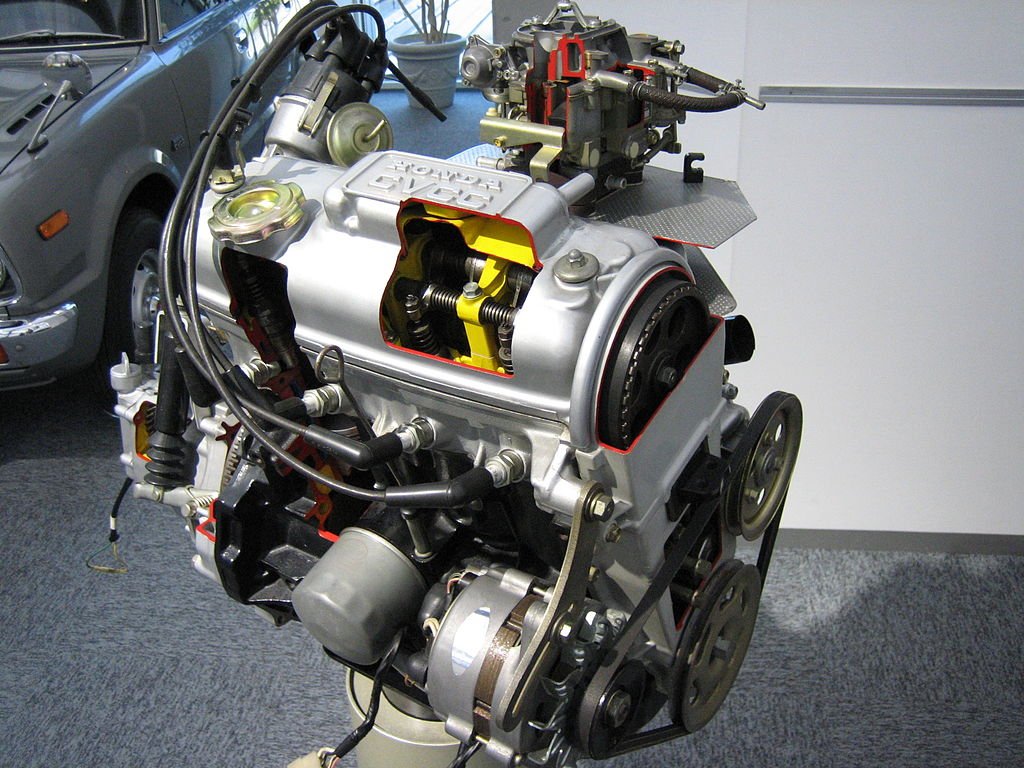

So what exactly sets this apart from conventional engines? The overall layout is similar, though there are a few differences. There is a small auxiliary combustion chamber around the spark plug.

Additionally, two separate intake valves are used on each cylinder. One is in the prechamber and the other is in the main chamber. The engine is fitted with a three-barrel carburetor. One throat leads directly to the prechamber. During the intake stroke, it provides a very rich air-fuel mixture of about 4:1. At the same time, The other two throats supply a lean mixture of about 20:1 to the main chamber. This also leads to the creation of a mix that lands somewhere in the middle. The rich mix located in the prechamber only accounts for about 5 percent of the overall composition. As a result, the air-fuel blend needs less fuel than a conventional engine and is even significantly leaner than stoichiometric.

When the piston rises during the compression stage, it pushes any of the rich mix that seeped into the main chamber back into the prechamber, ensuring that the blend remains stratified. The rich mixture at the top is easily ignited when the spark plug fires because they’re in close proximity to each other. The resulting flame ignites the moderate mixture in the middle, which then ignites the lean mix at the bottom.

More efficient fuel consumption cuts down on the amount of harmful pollutants that are emitted. There is more oxygen available in the leaner mix, which aids in converting carbon monoxide into carbon dioxide. Nitrous oxide is produced in greater quantities at higher temperatures. Here, most of the combustion process occurs near the air-starved pre-chamber. The flame doesn’t reach the main chamber until the expansion stroke. By this point, the temperature here has dropped considerably. And there's just enough fuel in the mix to ensure stable and reliable combustion. This allows it to maintain a consistent temperature and more thoroughly burn the resulting hydrocarbons.

1972 EPA TEST

The latter half of 1972 was a rather eventful time in the CVCC development cycle. Honda finished the construction of a prototype engine in the summer. In October, it officially debuted at the Akasaka Prince Hotel. It was also here that they made two bold claims. CVCC technology could be installed on existing engines, meaning that tooling at manufacturing facilities could be retained. Additionally, the integrated emissions control solution meant that after-the-fact devices such as catalytic converters weren’t necessary.

This event sent reverberations throughout the automotive world. No one expected Honda of all companies to be the first to break through the wall. Depending on who you spoke to, they either became the most innovative company in the space or the biggest target in the entire industry. Others, such as the EPA, needed to see it for themself to believe it. Honda previously submitted a report on their testing program as part of their annual status report, but the firm offered to perform tests of their own. Honda accepted the offer and sent three vehicles to their headquarters in Ann Arbor, Michigan that December.

This was a particularly odd time for the testing to occur. The engine was ready for it and the Civic had been introduced to the Japanese market that July, but a CVCC-equipped variant was still a few years out. Consequently, Honda was forced to ship out similar compact cars from other automakers. They tried to make it as one-to-one a comparison as possible, even going as far as to place sandbags in them to increase their weight.

The cars weren’t equipped with catalytic converters, thermal reactors, air injection or exhaust gas recirculation systems. Honda also ran the cars on unleaded fuel to see its long-term effects should it become mandatory in the future.

Two of the cars only had about 1,500 miles. The third, meanwhile, was set to undergo a rigorous 50,000-mile durability test to see what effect the additional wear and tear would have on the technology. It went off without a hitch. Some modifications were made at the 44,000 miles point of the test. There were minor changes to the carburetor, but none of this had any effect on the emission levels.

For the first test, the EPA set the cars up on a dynameter to simulate about 11 miles of city driving. The setup was close enough, with a bit of stop-and-go driving and speeds of up to 57 miles per hour. The first phase of the trial focused on emissions generated after a “cold start” where the cars sat for 12 hours before start up. After 7.5 miles, the cars sat shut off for 10 minutes before being fired up again to simulate a “hot start.”

Then the cars went through an older variant of this test at a higher payload without the “hot start” section. Lastly, emission samples were taken from the cars while at idle, 15, 30, 45, and 60 miles per hour.

Vehicle exhaust was drawn directly from the car, diluted with air, pumped into bags, and analyzed for the three pollutants in question. They are measured grams of exhaust generated per mile. Cars need to emit no more than 3.4g of CO, .41g of hydrocarbons, and 3.1g of NOx in order to pass the test and be in line with the 1975 regulations.

Things got off to a rocky start. One of the low-mileage cars suffered from a binding choke linkage during the first test. This was amended and the cars went on to CRUSH the remaining trials.

The CVCC posted lower emission levels than any other gasoline-powered engine without after-treatment ever tested by the EPA. It emitted 1.9g of carbon monoxide, .21g of hydrocarbons, and 3.1g of nitrous oxide per volume of exhaust generated in a mile of driving.

These were well under the 1975 requirements, though nitrous oxide levels would have to be reduced by a further 50% in order to meet the standards for 1976. Honda did emphasize that the cars were only meant to meet the ‘75 specs and weren’t specifically calibrated to target nitrous oxide. They even reported a BLISTERING quarter-mile time of 17.8 seconds.

This test wouldn’t be the last one that the company would have to go through, but it was a massive step in further legitimizing CVCC technology. The EPA published the results on December 18th, officially meaning that Honda was the first automaker to meet the 1975 emissions requirements

DETROIT RESPONDS

So, after years of hard work and countless sums of money, Honda had finally proven that it was possible to meet the upcoming regulations without catalytic converters. Other companies were sure to use this as inspiration to come to their own solutions. After all, if little old Honda could manage to do it, then surely they could too, right?

Well, it didn’t actually play out like that. Engineers from both Ford and General Motors said that the Cvcc wasn’t all it was cracked up to be. They claimed that the engine could consume up to 25 percent more fuel and suffer from a 25 percent drop in power output because of the slower turning and lower temperatures within the main chamber.

They also said that stretching out the combustion process beyond the piston's midway point on the expansion stroke meant there was less energy against the piston, resulting in less torque than a conventional engine. Additionally, the system would take away valuable space from vacuum accessories such as power brakes.

The emissions test did reflect an increase in fuel consumption. The average fuel economy of the cars was 20 percent lower than that of the average of the 2,000 pound 1973 certification vehicles tested by the EPA that year. Even still, the firm felt that Detroit’s concerns in this regard were a bit overblown. The CVCC test car was rated at about 70 horsepower as compared to other cars of similar weight in the 50 to 59HP range. It also essentially delivered the same power and fuel economy as the engine it was set to replace. As a result, the EPA felt that there was no significant tradeoff between clean operation, and power and fuel economy.

The engineers also didn't think it would be as easy to implement the technology as Honda claimed. Honda’s engine had a cylinder bore equal to 2.76 inches, and there were concerns whether or not it could be applied to V8s with 4-inch bores or more. Additionally, the system’s valve gear - a simple overhead camshaft with a basic rocker-arm arrangement to each of the three valves per cylinder - differed substantially from Detroit’s V8s which used pushrods from a camshaft in the block. Therefore, they claimed that a switchover to CVCC technology would require a complete change to how Detroit created automobiles.

Why was Detroit so hesitant to adopt the technology? There were a few reasons. Firstly, the Detroit Three had invested millions of dollars into catalytic converters. They didn’t seem to think that they were a stopgap until a more permanent solution came along like Honda did. Many companies were also set to release rotary-powered cars. CVCC technology had the potential to undermine their efforts in both of these areas. They were probably also motivated by a provision hidden in the Clean Air Act. If the industry couldn’t meet the standards after making every reasonable measure, then the EPA would grant an extension on the deadlines. If one company was able to meet them then the provisions go on as scheduled. The Japanese automotive industry, either naively or intentionally, interpreted this to only apply to major automakers. They didn’t consider Honda to be in this category. There would still be a possibility of an extension in their eyes. So the industry fought tooth and nail to tear the engine down.

All of this led Richard Gerstenberg, then the chairman of General Motors, to write the technology off entirely in 1973, saying:

“Well, I have looked into this design, and while it might work on some little toy motorcycle engine, I see no potential for it on one of our GM car engines.”

The quote itself isn’t nearly as noteworthy as what followed.

Honda wanted to prove that it could be easily and cheaply installed on Detroit’s cars. They actually began experimenting with the Chevrolet Vega as far back as 1972. They were able to successfully increase its fuel economy by 9 percent, from 17.2 miles per gallon to 18.9 miles per gallon. The comments from General Motors spurred the company to go one step further. Honda air-freighted an Impala to Japan. This was far removed from the 4-cylinder Vega that they had modified previously. The Impala was equipped with a massive 350 cubic-inch V8. This was precisely the kind of car that GM said wouldn’t benefit from CVCC. The engine was lightly modified. Its carburetor, manifold, and cylinder head were changed slightly. It was not necessary to change the engine to an overhead cam like in Honda’s engines. The car was not equipped with a catalytic converter, air pump, or exhaust gas recirculation technology. The modified cars were then sent back to the EPA for testing in the fall of 1973. It passed the requirements for ‘75 with ease. There were marginal gains in fuel consumption, but the mileage and drivability of the Impala were more than satisfactory.

Honda found that CVCC technology could save consumer’s money. When the Civic CVCC was introduced in 1975, it was between $100 to $200 more expensive than the standard model. They said that this added cost was more than offset by the savings from not using add-on devices. Estimations at the time pegged the cost of after-the-fact emissions control devices at about $350. This came from the materials need to make them, special servicing to maintain them, and a 10-15 percent decrease in fuel economy. Honda said that the CVCC could provide a $180 savings in overall cost. Additionally, the National Academy of Science estimated that a V8 engine fitted with the CVCC system would cost only $60 more to produce than a conventional V8.

Soichiro Honda was interviewed by Playboy Magazine, and when he was questioned about the matter, he said “when Congress passes new emissions standards, we hire 50 more engineers and GM hires 50 more lawyers.”

CVCC LICENSING

Soichiro Honda knew exactly what the company had on its hands. In the book The Honda Myth by Masaaki Sato, he said:

“The Muskie Act has given Honda a rare opportunity. We used it to arm ourselves with the powerful weapon of the CVCC. Now we’re in a position to go face-to-face with anyone, even foreign companies. No matter what people say, the CVCC is an earth-shattering, history-making development in automotive technology. Our suitors will be begging before we even ask.”

And beg they did. Automakers set aside their initial doubts and lined up to license the tech for their own cars. Honda made two sorts of deals with other companies.

The first provided them with limited access to CVCC technology. Automakers that took these deals included Chrysler and Isuzu. The second type of agreement gave them the ability to develop, build, and sell their own technology based on the CVCC architecture. This wouldn’t be an exclusive rights agreement, either. Honda planned to license CVCC to as many companies as they could. The first company to sign on with them was Toyota. Their system was officially introduced in 1975 as the TTC-V. TTC stands for Toyota Total Clean System and indicates a car that has emissions control technology. The V in the acronym stands for vortex and specifies the application of the CVCC technology.

Ford was also interested. The PROCO was becoming less viable with every passing minute. The company spent the better part of two decades developing it and it was no closer to seeing production. In the time that it had been stuck in product cycle purgatory, Honda had conceived and developed a solution of their own. They hoped that the PROCO could have some sort of payoff in the distant future, but, for the moment, they knew licensing the CVCC was their best chance to meet the regulations.

This wasn’t just about the upcoming deadlines, though. This was their ticket into the growing Japanese market.

In 1970, the number of cars produced in Japan exceeded 5 million cars. It was estimated that the number could exceed 7 million. Meanwhile, the number of cars produced in the United States fell to around 8 million because of a recession. It wasn’t outrageous to think that the Japanese auto market could match that of America’s.

General Motors and Chrysler had already formed relationships with automakers there. Ford could have been on equal footing with the others, but their talks with Mazda had seemingly broken down beyond repair. Rebuilding their Japanese strategy from scratch sent the company into a panic, so when Honda publicized the test results, Ford dropped everything and initiated contact.

Ford had already prepared plans that included the importing of engines, the sale of the Civic under the Ford name, joint development of compact cars, and even a capital tie-up.

Fujisawa wasn’t particularly keen on a full-scale alliance. He acknowledged that it might not be a bad idea, but a capital tie-up was out of the question. They couldn’t outright rebuff these demands, though. Turning a massive company like Ford away could potentially hurt them in negotiations with other companies. This also opened the door for Honda to sell their cars in the United States. I’ll get more in-depth with this side of the deal in a later video. For now, just know that, if all went according to plan, Honda had the chance to sell their cars in Ford dealerships. With all of this in mind, Honda cautiously went along with the talks.

General Motors also expressed interest in the technology. The Impala CVCC diversion wasn’t just a stunt. It was to show that it could actually work on their bread and butter V8 sedans. Honda desperately wanted them to take them up on the opportunity. Their reasons for this were similar to the potential Ford alliance. The difference here is that ⅔ of the 300 Honda dealerships in the United States were also affiliates of General Motors. Additionally, Honda could use their negotiations with GM as a bargaining chip in talks with Ford. Ideally, they’d be able to choose which of the two to sell their cars through.

Hideo Sugiura, a member of Honda’s board of directors, flew to Detroit in 1973 to discuss matters further. GM didn’t intend on licensing the technology. Instead, they planned on using Honda as a mere engine supplier. The company said they wanted to purchase between 200,000 and 400,000 CVCC engines. Honda had no interest in this arrangement. It would put GM in a clear position of power. Besides, Honda didn’t even have the infrastructure in place to fulfill that kind of order. Ford also brought up a similar subject, so even if they were interested in the proposal, it would be a breach of faith with Ford to pursue it any further.

Talks with Ford developed and the two sides came to an agreement in July of 1973. The Civic went on sale shortly after this and was a runaway success. Ford only became more interested in a tie-up, but what little interest Honda had in the idea completely dried up. They realized that they didn’t need the assistance of Ford, or anyone else, to succeed in the automotive market. Honda was an independent automaker. Still, they couldn’t just drop the deal. This wasn’t just because of the negative optics that would come from such a move. Honda’s corporate policy obligated them to return a favor. In this case, they agreed to help Ford sell its cars in Japan.

They rebranded their used-car sales division, Honda Chunan, to Honda International Sales Company, or HISCO. The two companies set an annual sales goal of 10,000 units a year. It didn’t get anywhere close to this. Ford’s offerings didn’t appeal to Japanese car buyers. Honda also resented how they tried to control everything, from the sales process to the layout of the showroom.

And then the Oil Crisis happened. Ford planned on putting the engines in the Pinto and Mustang but then ran into financial difficulties. Both sides finally had reason to put the troubled agreement to rest. General Motors also dropped their plans to install it into their compact cars. Honda was sorely disappointed to not have licensed the tech to one of the Detroit Three, but at the very least they were able to change how they were perceived by their contemporaries.

MARKET INTRODUCTION

The engine itself passed the 1975 standards way back in 1972, but the Civic CVCC needed to officially be certified by the EPA before it could be exported to the United States. Honda didn’t think there would be much of an issue. The car already passed the necessary emissions tests in Japan with ease and the cars that the firm tested back then, while not Civics, were a pretty close match to the real thing. Much to their surprise, the car actually failed the tests. Honda wasn’t going to give up after coming this far. They established a division within R&D to figure out what went wrong.

Several factors were at play. The two test areas differed by over 1,000 feet in elevation, resulting in a significant difference in air pressure. Additionally, while the same dynamometer was used for both tests, Honda’s unit was modified for easier testing on small cars. By far the biggest variation between the two tests was the differences in driving habits between American and Japanese drivers. Urban conditions in Japan encouraged sparing use of the gas pedal while the wide-open highways of America required more aggressive driving.

Using the data they gathered from their investigation, they were able to replicate the conditions of the test in order to determine whether the car could pass it. Honda brought the Civic CVCC before the EPA once again in November of 1974. It passed, and they also informed Honda that the car achieved the top rating for fuel economy.

I’d wager that there wasn’t a better time in the history of the universe for the Civic CVCC to go on sale than when it did. It became available for purchase in Japan in December of 1973. The Japanese auto industry was in a freefall. Domestic production as a whole fell by 7.5 percent. Honda was the ONLY company there to record a major increase in sales. Production on their side shot up to 430,000 cars that year and sales rose 21 percent compared to the previous year. Demand for the Civic was so strong that Honda actually discontinued production of their kei cars in order to build more of them.

It was the same story across the Pacific. The EPA rated the car at 27 miles per gallon in the city and 39 miles per gallon in the highway. Those numbers matched those of the Nissan Sunny, which was then the most fuel-efficient car in the world. At $2,729, the Civic was also the most affordable car on the market. For those that wanted to save money at the pump, the choice was obvious.

The CVCC Civic didn't replace the standard model. They were sold alongside each other. This wasn't the case for examples destined for California. The CVCC engine was standard equipment for cars sold in the Golden State.

The country was gripped by a gas shortage in the middle of the decade. This was made even worse for those that owned cars equipped with catalytic converters. They required unleaded fuel in order to function and it wasn't readily available at all service stations. The Civic CVCC could run on both, though ideally owners would be using unleaded because, well, you know.

Newspapers and magazines wrote at length about their so-called "miracle engine." Honda's American operations used this publicity to their advantage. They photocopied every article they could find and then sent them off to major dealerships. Re tailers, in turn, came to American Honda in droves hoping they'd get a franchise of their own. Sales skyrocketed from there. 43,000 CVCC-powered Civics were sold in the United States in 1974. Sales for the brand swelled to 102,000 in 1975, making them the fourth-largest foreign automaker in the country behind Volkswagen, Toyota, and Nissan.

EPILOGUE

Honda’s CVCC technology was an astonishing engineering achievement, but the industry as a whole struggled to meet the rapidly approaching regulations. In March of 1973, The EPA held a hearing in the nation’s capital to see whether they should be implemented as scheduled. Honda and Mazda were the only two companies that could meet the standards. The EPA tried to come to some sort of compromise. They asked Honda if they could supply engines to the other automakers, but, for reasons we went through earlier, this wasn’t a viable option. The companies begged for an extension and the EPA finally caved.

Richard Nixon signed the delay into law in 1974. The standards for carbon monoxide and hydrocarbons were pushed back until 1977 while the standards for nitrogen oxides were delayed until 1978. Automakers could also seek another delay on the provisions if they still weren’t able to satisfy them.

Honda used CVCC to ride out the rest of the decade. They were able to avoid using a cat on their American-market cars until 1980. It began showing its age as emissions standards became more stringent at home and abroad. The second-generation Civic had two engines available with CVCC technology. Its 1500cc motor required the use of a catalytic converter to get by. This meant that it could no longer run on leaded gasoline; a Shakespearean tragedy, let me tell you. The smaller 1,300cc engine could use both, but it was not available in California and high-altitude areas.

Things were a bit more exciting across the Pacific. The technology was dubbed CVCC II as it entered the 1980s. This version used two side draft carburetors instead of a single twin-choke carb to provide the appropriate fuel mixes. It made its way onto the Prelude and Accord, but the City Turbo was by far the most off-the-wall car that used it. The City utilized a version of CVCC called Compact Blazing-Combustion Axiom, or COMBAX for short.

It utilized forced induction and also debuted Honda’s PGM-FI digital fuel injection system. So how do these systems work together? The CVCC process is strikingly similar to that of its carbureted forebears, with injectors supplying a rich mixture to the prechamber and a lean mixture to the main chamber. CVCC technology is particularly useful in a turbocharged car because it helps to ward off detonation. This occurs when two flames collide in a combustion chamber. One is caused by the spark plug and the other is caused by immense pressure and friction igniting the fuel mix on the other side of the chamber. The second kind of flame is less likely to happen in the City Turbo, as the mixture in the main chamber is far too lean to reliably ignite on its own.

Emissions regulations tightened even further, which caused Honda to saddle the system down with hoses, sensors, and solenoids, transforming it from an elegantly simple solution to a complex monster. It became more trouble than it was worth. There were easier ways to meet the regulations. CVCC didn’t even make it out of the decade. Honda fully embraced PGM-FI and began phasing the technology out.

Even still, stratified charge engines found a way to carry on. General Motors, Mitsubishi, Nissan, and Fist were some of the other companies that developed ones of their own, and while they never saw production, they do illustrate just how influential Honda was in the automotive industry. A few systems did reach the market as well. Jaguar affixed the H.E. moniker on such equipped V12 models in the 80s to indicate “high-efficiency” variants. Mercedes’ Blue Direct line and Volkswagen’s TFSI lines are more recent examples that saw the light of day.

The mid-70s were the start of a tumultuous period in the car industry. While most other automakers struggled to adapt to the evolving automotive landscape, Honda took on the challenge in stride. It's no exaggeration to say that Honda wouldn't have the foothold it currently has in the American market if it weren't for the CVCC Civic. This is just another shining example of the Power of Dreams.